Ceramic Capacitors

|

Name

|

Download

|

Capacitance

|

Voltage Rated AC

|

Tolerance

|

Mounting

|

Operating Temp

|

RoHS

|

Voltage Rated DC

|

Case size

|

|---|---|---|---|---|---|---|---|---|---|

| CEC5X Series | 10nF ~ 6.8µF | - | ±1%, ±2%, ±5%, ±10%, ±20% | SMD, DIL | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 500V | 5550, 3033, 3740, 6080, 8060, 80150, 40140 | |

| CNC3X Series | 1.2µF ~ 68µF | - | ±10%, ±20% | SMD, DIL | -55°C ~ 125°C | ROHS, Non ROHS | 16V ~ 25V | 2220, 2528, 3333, 4040 | |

| CNC5X Series | 100nF ~ 180µF | - | ±10%, ±20% | SMD, DIL | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 500V | 5550, 3033, 3740, 6080, 8060, 80150, 40140 | |

| CNC8X Series (Chips) | 47nF ~ 27µF | - | ±10%, ±20% | SMD | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 400V | 3333, 4040, 5440, 6560, 3080, 33110 | |

| CNC8X Series (STACK) | 47nF ~ 180µF | - | ±10%, ±20% | SMD, DIL | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 400V | 3333, 4040, 5440, 6560, 3080, 33110, 80150 | |

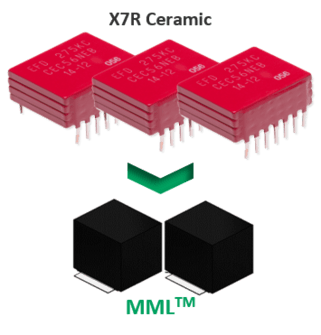

| Miniature Micro-Layer Capacitors | 1µF ~ 1000µF | - | - | SMD DIL Screw | -55°C ~ 140°C | ROHS, Non ROHS | 100V ~ 1200V | - | |

| R Series (Chips) | 47nF ~ 27µF | - | ±10%, ±20% | SMD | -55°C ~ 125°C | ROHS, Non ROHS | 50V ~ 500V | 2225, 5550, 6560, 3033, 3740, 6080, 8060, 45107 | |

| R Series (Leaded) | 47nF ~ 27µF | - | ±10%, ±20% | Radial | -55°C ~ 125°C | ROHS, Non ROHS | 50V ~ 500V | - | |

| SC / SV Series | 47nF ~ 390µF | - | ±10%, ±20% | Radial, Ribbon, DIL SMD | -55°C ~ 125°C | ROHS, Non ROHS | 50V ~ 500V | 2225, 5550, 6560, 3033, 3740, 6080, 8060, 45107, 45214, 80150, 125205 | |

| TCN8X Series | 470nF ~ 120µF | - | ±10%, ±20% | Radial | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 500V | - | |

| TCP/TCV 5X Series (TCP54) | 100nF ~ 180µF | - | ±10%, ±20% | Radial | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 500V | 5550, 3033, 3740, 6080, 8060, 80150, 40140 | |

| TCP/TCV 8X Series | 47nF ~ 180µF | - | ±10%, ±20% | Radial | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 400V | 3333, 4040, 5440, 6560, 3080, 80150 | |

| TEF Series | 10nF ~ 680nF | - | ±1%, ±2%, ±5%, ±10%, ±20% | Radial | -55°C ~ 125°C | ROHS, Non ROHS | 63V ~ 500V | - |

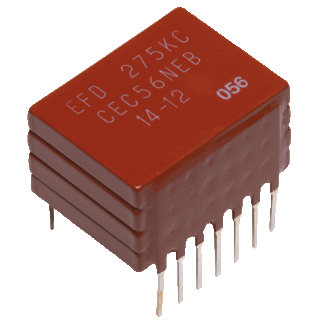

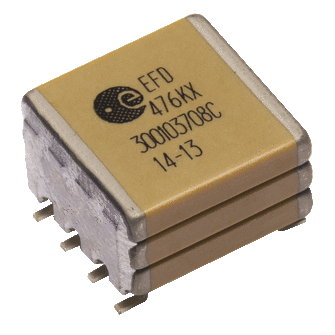

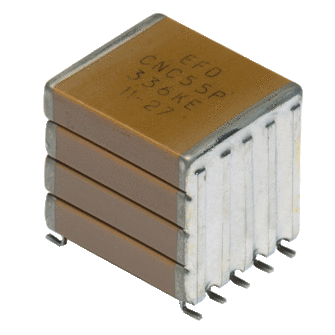

Ceramic Capacitors

Exxelia offers a diverse portfolio of multi-layer ceramic capacitors (MLCCs) including low and high voltage, high capacitance values, and high-temperature resistance (up to 250°C). Exxelia ceramic capacitors are manufactured using Precious Metal Electrode (PME) technology which grants superior reliability and durability in challenging environments like aviation engines, oil exploration, and medical implants, pulse applications up to space applications. Indeed, Exxelia ceramic capacitors meet stringent quality standards, including numerous ESA QPL qualifications. Exxelia also offers custom design solutions and a non-obsolescence policy, supported by industrial tooling suitable for both high and low quantities, to meet specific project requirements effectively.

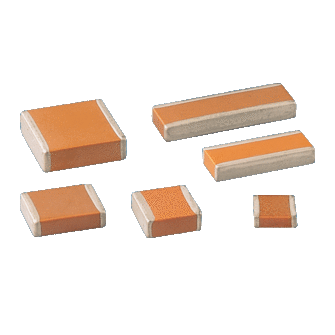

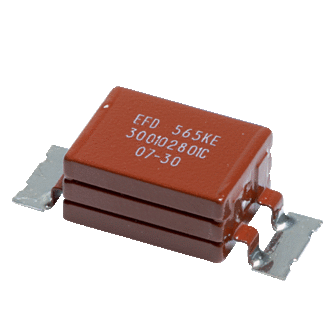

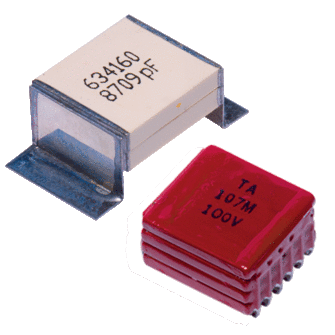

Our chip ceramic capacitors are available in a range of temperature coefficients such as NPO, 2C1, BR, and X7R, catering from industrial to military and even space-grade requirements. They come in all standard EIA sizes with multiple terminations (including an optional nickel barrier / non-magnetic variant) to ensure compatibility with any soldering technique. They can also be declined with different finishes (varnished, encapsulated, molded or conformal coated ceramic capacitors) and with different leads styles: DIL and ribbon leads for surface mounted ceramic capacitors ; or axial, radial or through hole N-style DIL for through-hole ceramic capacitors.

Designed with advanced ceramic technology, our high-capacitance ceramic capacitors offer reliability and compact size for switched mode power supplies (SMPS) and DC-DC converters, ideal for hybrid assemblies and low-profile circuit designs.

Our high-voltage MLCCs are offered in class 1 (NPO), class 2 (X7R), and C48X dielectrics, providing substantial size and space advantages. Available in chip, molded / conformal coated (radial leads), and stacked forms, these capacitors are well-suited for high-voltage power supplies, multipliers, and high-reliability military and space applications.

Exxelia's high-temperature ceramic capacitors utilize class 1 or class 2 ceramic dielectrics made from high-purity oxides, ensuring performance up to 250°C in both chips, stacked and leaded configurations.

Exxelia widely used ceramic High-Q MLCC capacitors are designed with P100 or ultra-stable NPO dielectric. These RF microwave capacitors can be used in high voltage applications up to 7200V. For high-frequency high power, high voltage applications such as MRI, NMR, RF generators for laser, plasma applications, power filters, Exxelia has developed the CP and CL series available in large sizes.