SVM Bus bars

Filtre

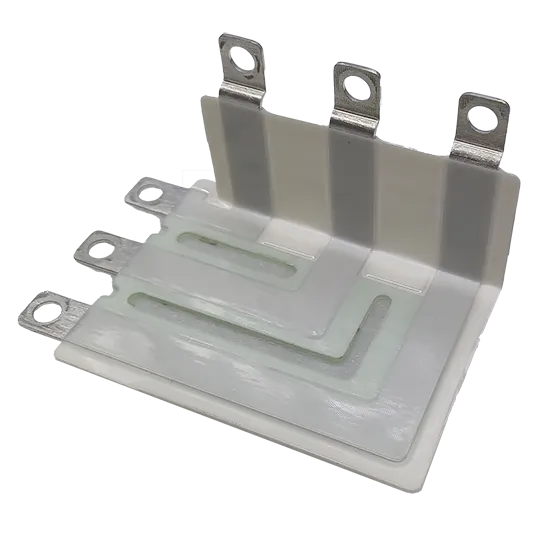

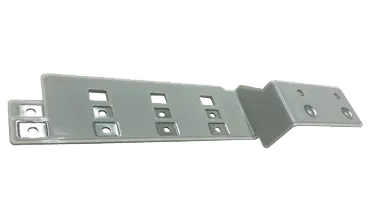

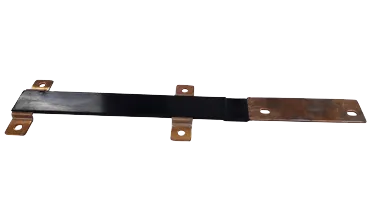

Powder Coated bus bar copper

Custom example

Bus bar type

Epoxy powder coated

Length

350mm

Width

390mm

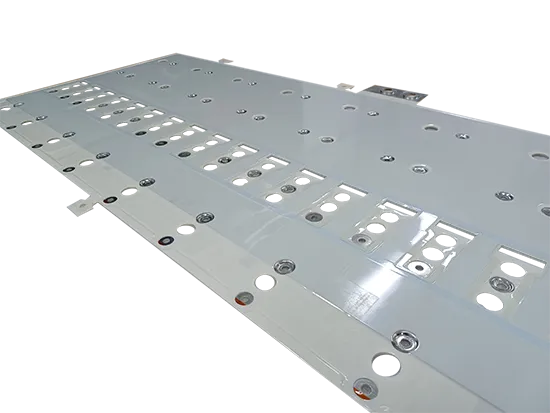

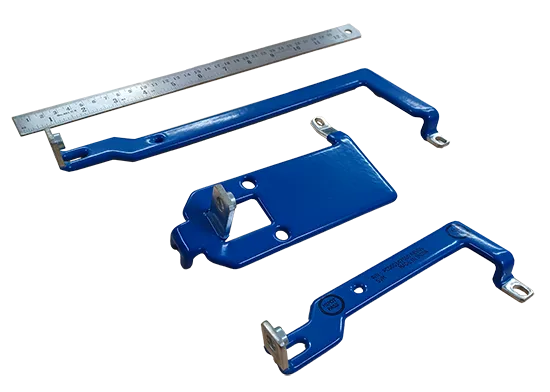

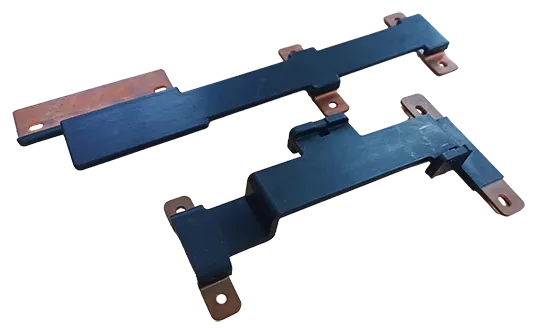

Powder Coated bus bar Aluminium

Custom example

Bus bar type

Epoxy powder coated

Length

290mm

Width

90mm

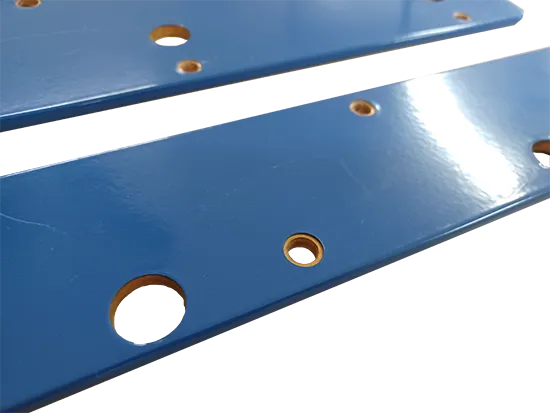

Powder Coated bus bar Aluminium 2

Custom example

Bus bar type

Epoxy powder coated

Length

510mm

Width

110mm

|

Name

|

Download

|

Bus bar type

|

Length

|

Width

|

Height

|

Conductor

|

Conductor thickness

|

Plating

|

Operating Temp

|

|---|---|---|---|---|---|---|---|---|---|

| Large dimension bus bar | Laminated | 1200mm | 600mm | - | Aluminum | 1mm | Nickel | 105°C | |

| High voltage bus bar | Laminated | 400mm | 215mm | - | Copper | 5mm | Tin | 105°C | |

| 90° angle bus bar | Laminated | 90mm | 80mm | 40mm | Copper | 1mm | Nickel, Gold | 105°C | |

| Bus bar with accessories | Laminated | 350mm | 390mm | 65mm | - | 0.75mm | - | 105°C | |

| High temp bus bar | Laminated | 550mm | 450mm | 50mm | Aluminum | 1.5mm | Tin | 130°C | |

| Very high temp bus bar | Laminated | 510mm | 205mm | 50mm | Aluminum | 1.5mm | Tin | 180°C | |

| Partially laminated bus bar | Laminated | 500mm | 210mm | 40mm | Copper | 1mm | Tin | 105°C | |

| Powder Coated bus bar copper | Epoxy powder coated | 350mm | 390mm | 65mm | Copper | 3mm | Tin, Gold | 130°C | |

| Powder Coated bus bar Aluminium | Epoxy powder coated | 290mm | 90mm | 25mm | Aluminum | 1mm | Tin, Gold | 130°C | |

| Powder Coated bus bar Aluminium 2 | Epoxy powder coated | 510mm | 110mm | 50mm | Aluminum | 6mm | - | 130°C | |

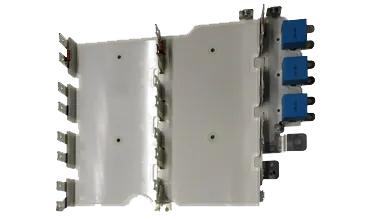

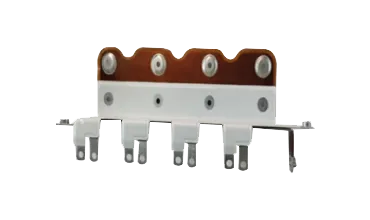

| Sub-assembly bus bar | Epoxy powder coated | 500mm | 320mm | 105mm | Copper | 2mm ~ 3mm | Tin | 130°C | |

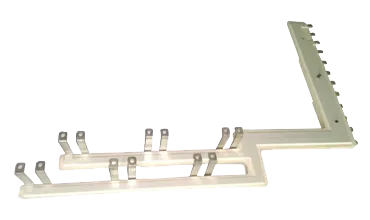

| PVC bus bar 1 | Kobosol-4 molded | 1200mm | 140mm | 50mm | Copper | 3mm | - | - | |

| PVC bus bar 2 | Kobosol-4 molded | 290mm | 90mm | 35mm | Copper | 2mm | - | - |

New

Large dimension bus bar

Custom example

New

High voltage bus bar

Custom example

New

90° angle bus bar

Custom example

New

Bus bar with accessories

Custom example

New

High temp bus bar

Custom example

New

Very high temp bus bar

Custom example

New

Partially laminated bus bar

Custom example

New

Powder Coated bus bar copper

Custom example

New

Powder Coated bus bar Aluminium

Custom example

New

Powder Coated bus bar Aluminium 2

Custom example

New

Sub-assembly bus bar

Custom example

New

PVC bus bar 1

Custom example

New

PVC bus bar 2

Custom example

SVM Bus bars

Exxelia SVM product offer includes:

Laminated bus bars - up to 4 layers for complex requirements

Powder coated bus bars - using epoxy powder coating for superior electrical insulation properties

PVC molded bus bars - overmolding with Kobasol-4, a soft and flexible insulation even after molding

Bare copper bus bars - multiple bends / formed bus bars using Copper as per ASTM B152 C11000 (ETP)

The following finishes are also available: tin, nickel, silver or gold plating.

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact