Laminated bus bars

Filtre

|

Name

|

Download

|

Bus bar type

|

Length

|

Width

|

Height

|

Conductor

|

Conductor thickness

|

Plating

|

Operating Temp

|

|---|---|---|---|---|---|---|---|---|---|

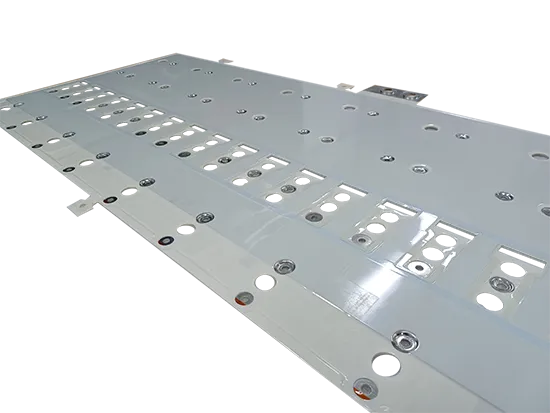

| Large dimension bus bar | Laminated | 1200mm | 600mm | - | Aluminum | 1mm | Nickel | 105°C | |

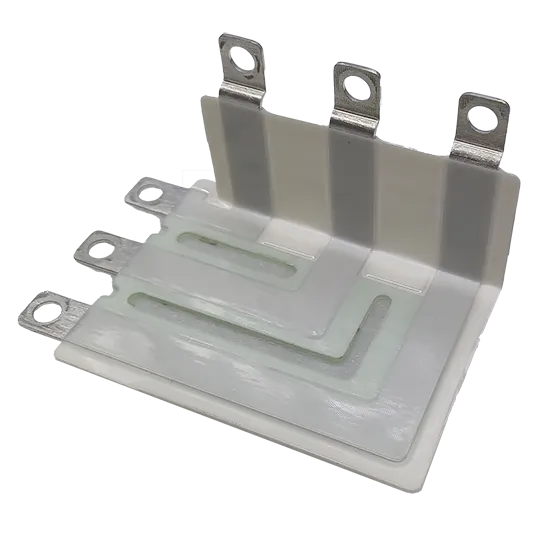

| High voltage bus bar | Laminated | 400mm | 215mm | - | Copper | 5mm | Tin | 105°C | |

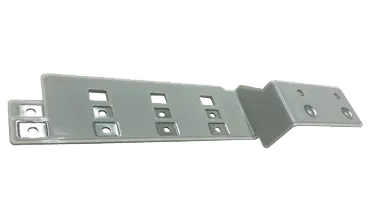

| 90° angle bus bar | Laminated | 90mm | 80mm | 40mm | Copper | 1mm | Nickel, Gold | 105°C | |

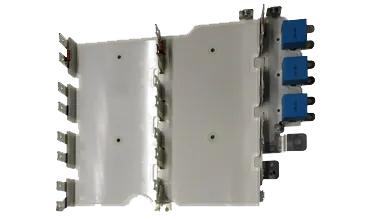

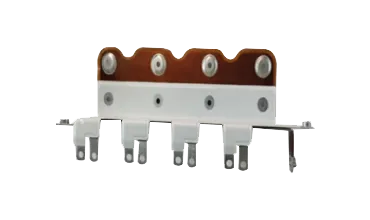

| Bus bar with accessories | Laminated | 350mm | 390mm | 65mm | - | 0.75mm | - | 105°C | |

| High temp bus bar | Laminated | 550mm | 450mm | 50mm | Aluminum | 1.5mm | Tin | 130°C | |

| Very high temp bus bar | Laminated | 510mm | 205mm | 50mm | Aluminum | 1.5mm | Tin | 180°C | |

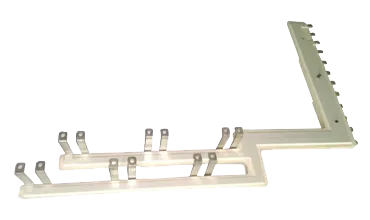

| Partially laminated bus bar | Laminated | 500mm | 210mm | 40mm | Copper | 1mm | Tin | 105°C |

New

Large dimension bus bar

Custom example

New

High voltage bus bar

Custom example

New

90° angle bus bar

Custom example

New

Bus bar with accessories

Custom example

New

High temp bus bar

Custom example

New

Very high temp bus bar

Custom example

New

Partially laminated bus bar

Custom example

Laminated bus bars

Exxelia’s multilayers laminated bus bars offer unmatched electrical performance and compact design for critical applications. Engineered to optimize power distribution, these bus bars reduce inductance, improve reliability, and ensure efficient thermal management. Available with tin, nickel, silver or gold plating, they provide superior durability and conductivity for industries such as medical, industrial applications and renewable energy.

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact