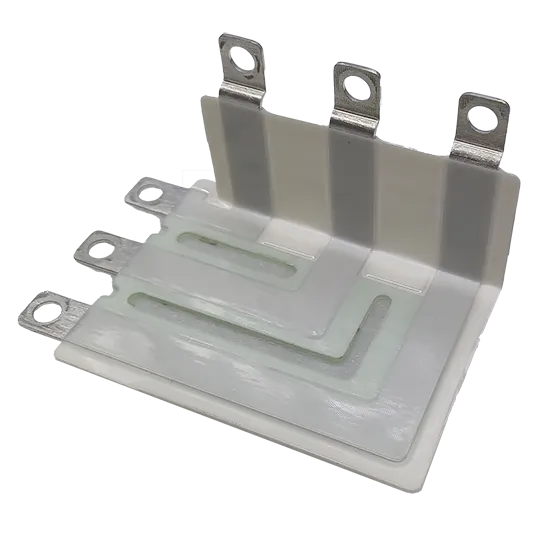

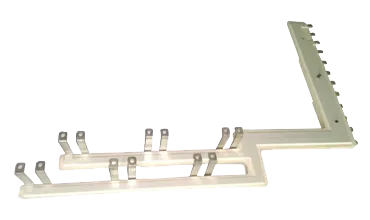

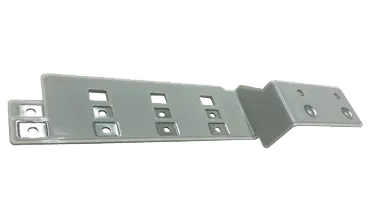

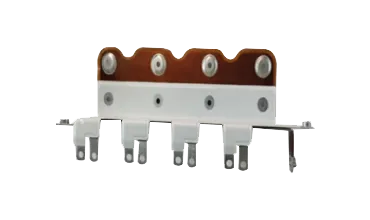

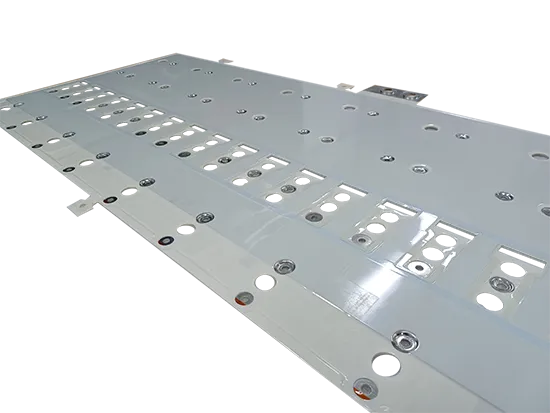

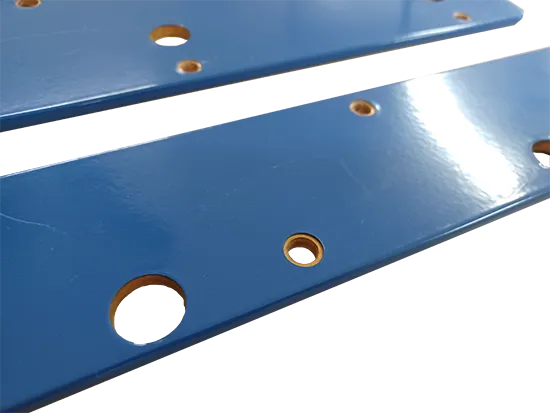

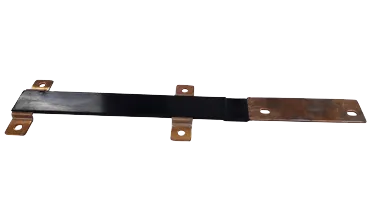

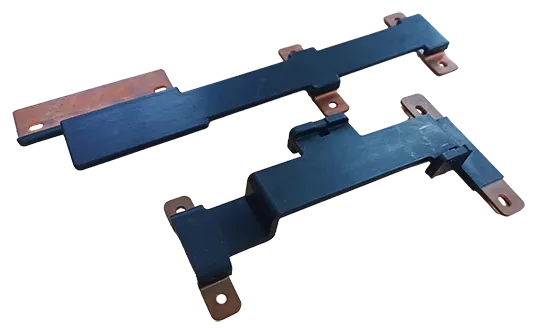

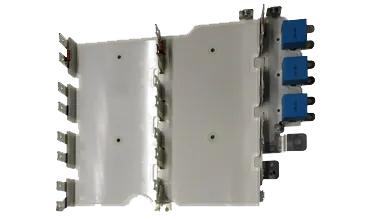

- Laminated bus bars are manufactured under unique process control. Pet films/insulations sheets were cut using CNC machines. Conductor is placed between two insulation films and then laminated.

- Insulation thickness is based on Hi POT requirements. Multi-layer bus bars are fabricated with inter layer insulation where ever necessary.

-

Bus bar type

Laminated

-

Length

350mm

-

Width

390mm

-

Height

65mm

-

Conductor thickness

0.75mm

-

Operating Temp

105°C

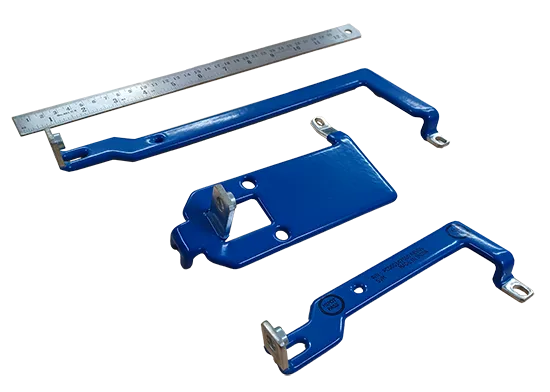

Typical applications :

- Interconnection of Capacitor Links, DC Link, IGBT Power Module, Power and Measuring Components, High Current Inductors etc for various markets like Power Electronics, Wind Energy, Solar Energy, Aerospace Application, Military Application, and Transportation.

Compliance and certifications

UL 94V0

RoHS

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact