Precision Potentiometers

|

Name

|

Download

|

Operating Temp

|

Diameter (Outside Diameter)

|

Mounting

|

Sealing

|

Housing Diameter

|

Length

|

Weight

|

Vibrations

|

Shocks

|

Resolution

|

Accuracy

|

Rotation speed

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

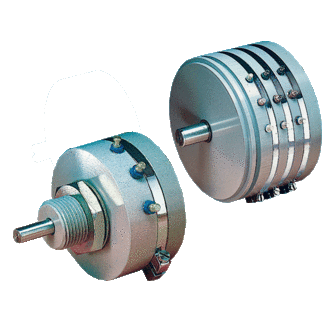

| 7300 Series | -55°C ~ 155°C | - | Servo, Bushing | - | 10mm ~ 80mm | 44.5mm | 85g | 20g.acc | 50g.acc | - | - | - | |

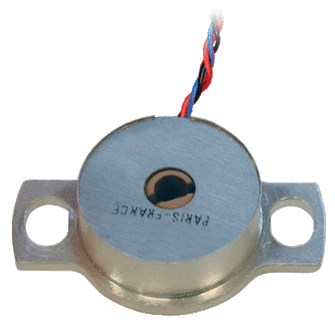

| C0104 Series | -55°C ~ 125°C | 10.4mm | Pancake | IP40 | 0mm ~ 20mm | 5mm | 2g | 20g.acc | 50g.acc | - | - | - | |

| C1509 Series | -55°C ~ 70°C | 22.2mm | Pancake | - | 20mm ~ 30mm | 4.5mm | - | 20g.acc | 50g.acc | - | - | - | |

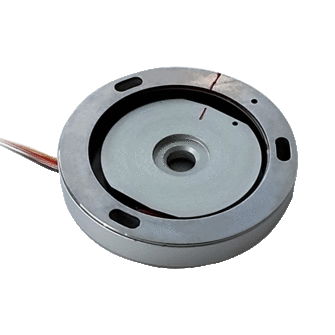

| C1516 Series | -40°C ~ 85°C | 40.55mm | Pancake | - | 30mm ~ 45mm | 6.7mm | 15g | 0.01g.acc | 180g.acc | - | - | - | |

| C9209 Series | -55°C ~ 125°C | 22.2mm | Servo, Bushing | - | 20mm ~ 30mm | 12.5mm | 13g | 20g.acc | 50g.acc | - | - | - | |

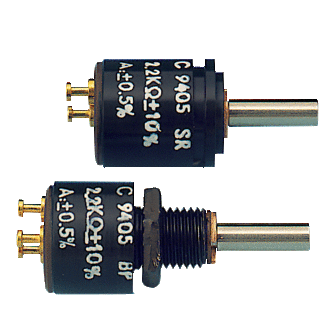

| C9405 Series | -55°C ~ 125°C | 12.7mm | Servo, Bushing | IP50 | 0mm ~ 20mm | 12.8mm | 10g | - | - | - | - | - | |

| M1505 Series | -45°C ~ 125°C | 22mm | Servo, Bushing | IP50 | 20mm ~ 30mm | 12.5mm | 60g | - | - | - | - | - | |

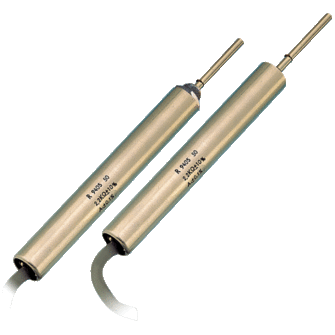

| R1504 Series | -45°C ~ 125°C | 9mm | Linear | IP50 | - | 178mm | - | 20g.acc | 50g.acc | - | - | - | |

| R9209 Series | -55°C ~ 125°C | 22.3mm | Servo, Bushing | - | - | 126mm | - | 20g.acc | 50g.acc | - | - | - | |

| R9405 Series | -55°C ~ 125°C | 12.7mm | Servo, Bushing | IP50 | - | 142mm | - | 20g.acc | - | - | - | - | |

| R9503 Series | -25°C ~ 125°C | 8mm | Linear | IP50 | - | 78mm | - | - | - | - | - | - |

Precision Potentiometers

For over 50 years, Exxelia has been a trusted leader in the development of high-precision potentiometers, specifically designed for aerospace, space and military applications. These potentiometers, available in rotary and linear configurations, deliver exceptional accuracy with linearity up to <0.01%.

Exxelia also offers custom potentiometers to respond to all mechanical, thermal, and environmental demands, ensuring they perform in the most extreme conditions including under vacuum.

Exxelia’s potentiometers are widely used in space applications such as satellites (solar array drive mechanisms, pointing systems), space exploration rovers, and critical space instruments. With our expertise in space-qualified potentiometers, we provide tailored solutions that meet the rigorous standards of the space industry. Our potentiometers come in all sizes, from miniature to large-scale, with RoHS-compliant options. Exxelia’s custom designs and bearingless sensor solutions are ideal for space missions where reliability and precision are paramount.

With decades of experience in high reliability potentiometers (including space-grade potentiomètres), Exxelia is the go-to partner for aerospace companies and space agencies looking for advanced, reliable potentiometer solutions for their space missions.