Subsystems

Filtre

Train Detection system (on railway path)

Custom example

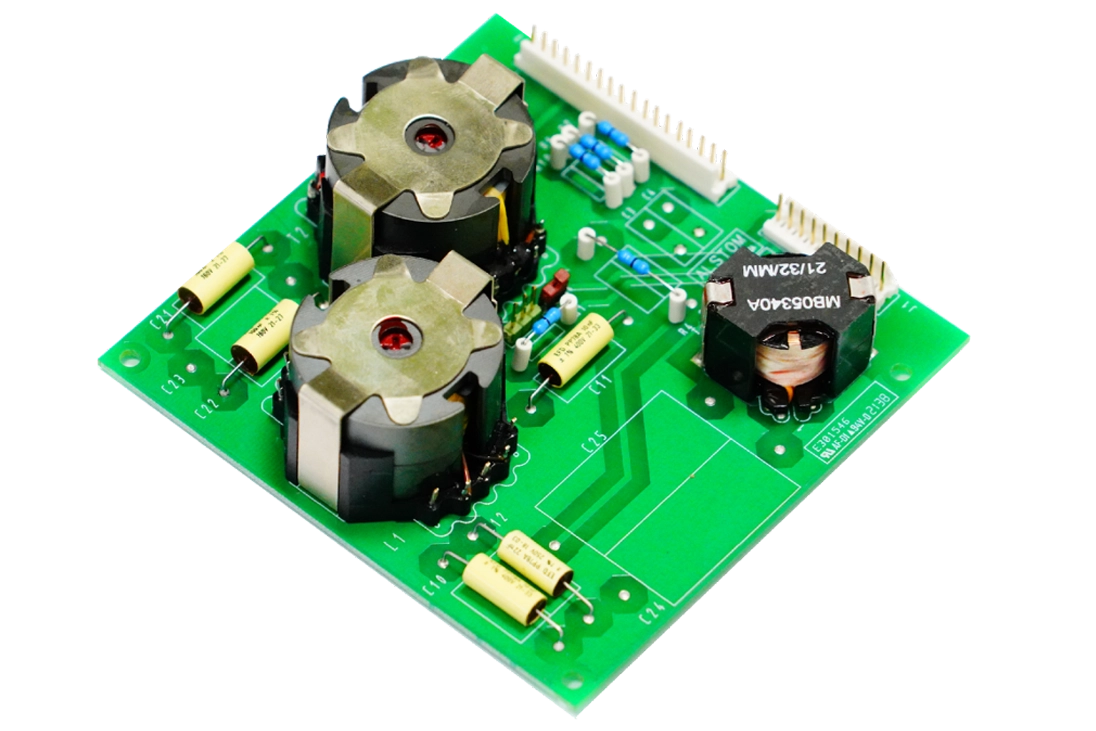

Firtering Boards for train detection systems

Custom example

|

Name

|

Download

|

Operating Temp

|

Height

|

Mounting

|

Frequency

|

Power

|

Current

|

Inductance

|

Peak Current

|

RoHS

|

Accuracy

|

Ratio

|

Diameter (Outside Diameter)

|

Length

|

Weight

|

Notes

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Train Detection system (on railway path) | - |

- | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Firtering Boards for train detection systems | - |

- | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Train Detection system (on railway path)

Custom example

Firtering Boards for train detection systems

Custom example

Subsystems

Exxelia propose also complex winding products, sub-assembly or turnkey solution that integrate our magnetics components

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service

Contact