Magnetic Winding

|

Name

|

Download

|

Operating Temp

|

Diameter (Outside Diameter)

|

Length

|

Weight

|

Notes

|

|---|---|---|---|---|---|---|

| Stator 250 | - | 250mm | 350mm | 200Kg | - | |

| Rotor 30 | - | 30mm | 70mm | 200g | - | |

| Stator 40 | - | 40mm | 75mm | 400g | - | |

| Rotor 20 | - | 20mm | 55mm | 150g | - | |

| Stator 70 | - | 70mm | 80mm | 1.8Kg | - | |

| Rotor 25 | - | 25mm | 40mm | 180g | - | |

| Stator 75 | - | 75mm | 50mm | 300g | - | |

| Rotor 40 | - | 40mm | 50mm | 200g | - | |

| Stator 100 | - | 100mm | 120mm | 3.8Kg | - | |

| Stator 20 | - | 20mm | 30mm | 80g | - | |

| Stator 180 | - | 180mm | 120mm | 8Kg | - | |

| Motor & Stator | -60°C ~ 120°C | 100mm | 120mm | 3.8Kg | for flight control | |

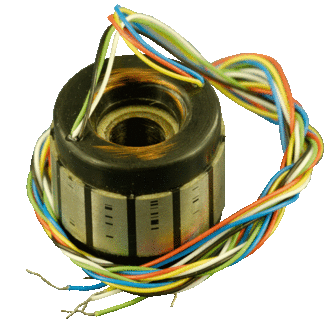

| Double Section Bobin | - |

-55°C ~ 130°C | 120mm | 140mm | 30g | - |

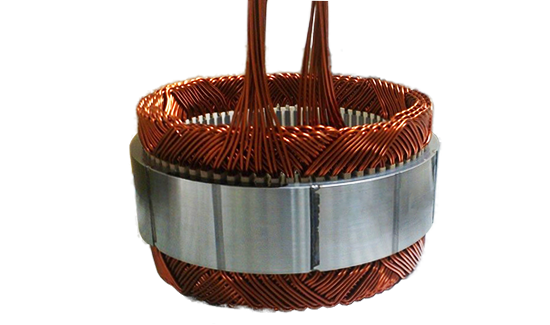

Magnetic Winding

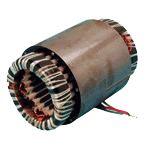

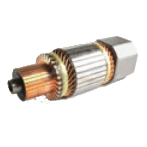

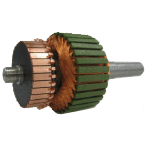

Exxelia offers industrialization support and technology expertise in the development of stators for use up to 220°C, crucial in various aerospace applications such as actuators and ventilation systems, including cabin, galley cooling, and heating systems. Our expertise extends to advanced technologies like RAM air turbines, which require precise engineering and reliability.

With a robust engineering background in winding, molding, and manufacturing competencies, Exxelia provides optimized solutions for the ramp-up and mass production of stators. Our capabilities include innovative processes such as overmolding and impregnation, whether wet or vacuum, ensuring the durability and performance of critical components like engine and braking cooling systems and alternators.

Exxelia has developed significant expertise in controlling Partial Discharge, a key factor in ensuring low aging and extended Mean Time Between Failures (MTBF) of our products, even in high voltage systems. This ensures our components maintain their reliability and performance over extended periods, supporting the rigorous demands of the aerospace industry.