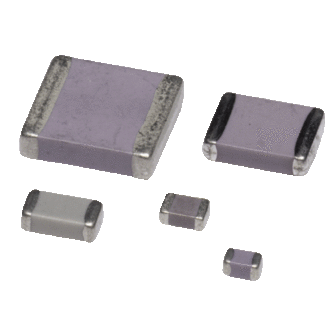

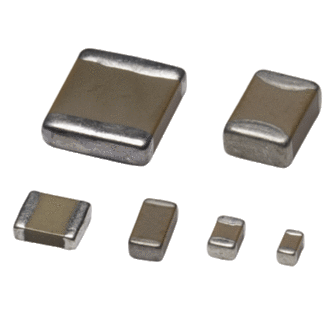

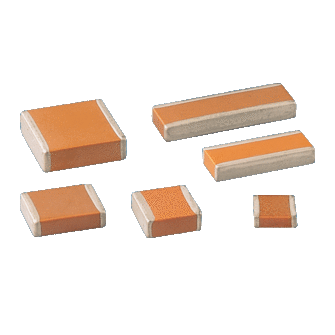

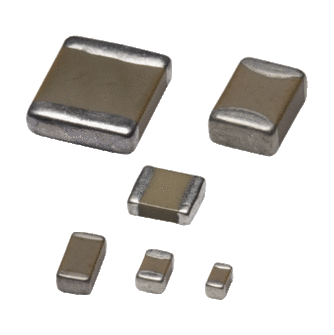

- Miniaturization

- High-Rel capacitors

- High capacitance values

- Formerly under the reference: CNC1, CNC12, CNC14, CNC19, CNC2, CNC4, CNC6, CNC7

-

Capacitance

10pF ~ 12µF

-

Tolerance

±1%, ±2%, ±5%, ±10%, ±20%, ±0.25%, ±0.5%

-

Mounting

SMD

-

Operating Temp

-55°C ~ 125°C

-

RoHS

ROHS, Non ROHS

-

Voltage Rated DC

10V ~ 1000V

-

Case size

402, 403, 603, 504, 805, 907, 1005, 1206, 1210, 1605, 1806, 1812, 1825, 2210, 2220, 2225, 2528, 3030, 3040

Typical applications :

- DC Filtering

- Decoupling

The below Part Numbers reflect our high runners only.

Please contact us if you can't find your specifications.

|

PN

|

Capacitance

|

Voltage Rated AC

|

Tolerance

|

Mounting

|

Operating Temp

|

RoHS

|

Voltage Rated DC

|

Case size

|

|---|---|---|---|---|---|---|---|---|

| CNC1 - - G W - F 124 K 100 - - | 120000pF | - | ±10% | SMD | - | ROHS | 10V | 0504 |

| CNC1 - - - - F 470pF +/-10% 50 V S8 - | 470pF | - | ±10% | SMD | - | Non ROHS | 50V | 0504 |

| CNC1 - C - - - 330pF +/-10% 63 V - - | 330pF | - | ±10% | SMD | - | Non ROHS | 63V | 0504 |

| CNC1 - - - - 330pF +/-10% 63V | 330pF | - | ±10% | SMD | - | Non ROHS | 63V | 0504 |

| CNC1 - - - - - 470pF +/-20% 63 V - - | 470pF | - | ±20% | SMD | - | Non ROHS | 63V | 0504 |

| CNC1 - - - - - 470pF +/-20% 63 V S8 - | 470pF | - | ±20% | SMD | - | Non ROHS | 63V | 0504 |

| CNC1 - C W - - 4700pF +/-10% 63 V - - | 4700pF | - | ±10% | SMD | - | ROHS | 63V | 0504 |

| CNC1 - - E W - - 4700pF +/-10% 63 V - - | 4700pF | - | ±10% | SMD | - | ROHS | 63V | 0504 |

| CNC1 - - - - F 470pF +/-10% 100 V - - | 470pF | - | ±10% | SMD | - | Non ROHS | 100V | 0504 |

| CNC1 - - - - F 470pF +/-10% 100 V S8 - | 470pF | - | ±10% | SMD | - | Non ROHS | 100V | 0504 |

| CNC1 - - - - F 2200pF+/-10% 100 V - - | 2200pF | - | ±10% | SMD | - | Non ROHS | 100V | 0504 |

| CNC1 - - - - F 2200pF+/-10% 100 V S8 - | 2200pF | - | ±10% | SMD | - | Non ROHS | 100V | 0504 |

| CNC12 - - 02 - - S 1.5µF +/-5% 10 V - Lev FM | 1500000pF | - | ±5% | SMD | - | Non ROHS | 10V | 1206 |

Compliance and certifications

CECC

ESA

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact