Typical applications :

- DC Links, Power Converters, Energy Management

- Payloads, Telemetry, SADR

- Flight Controls, Propulsion Control

- Generators

- Charge/discharge, Generators, Electric Motors and more

|

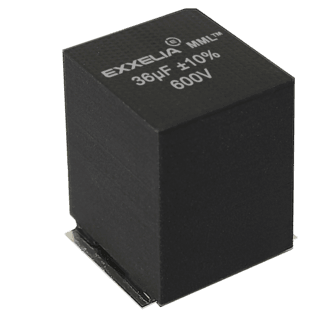

PN

|

Capacitance

|

Voltage Rated AC

|

Tolerance

|

Mounting

|

Operating Temp

|

RoHS

|

Voltage Rated DC

|

|---|---|---|---|---|---|---|---|

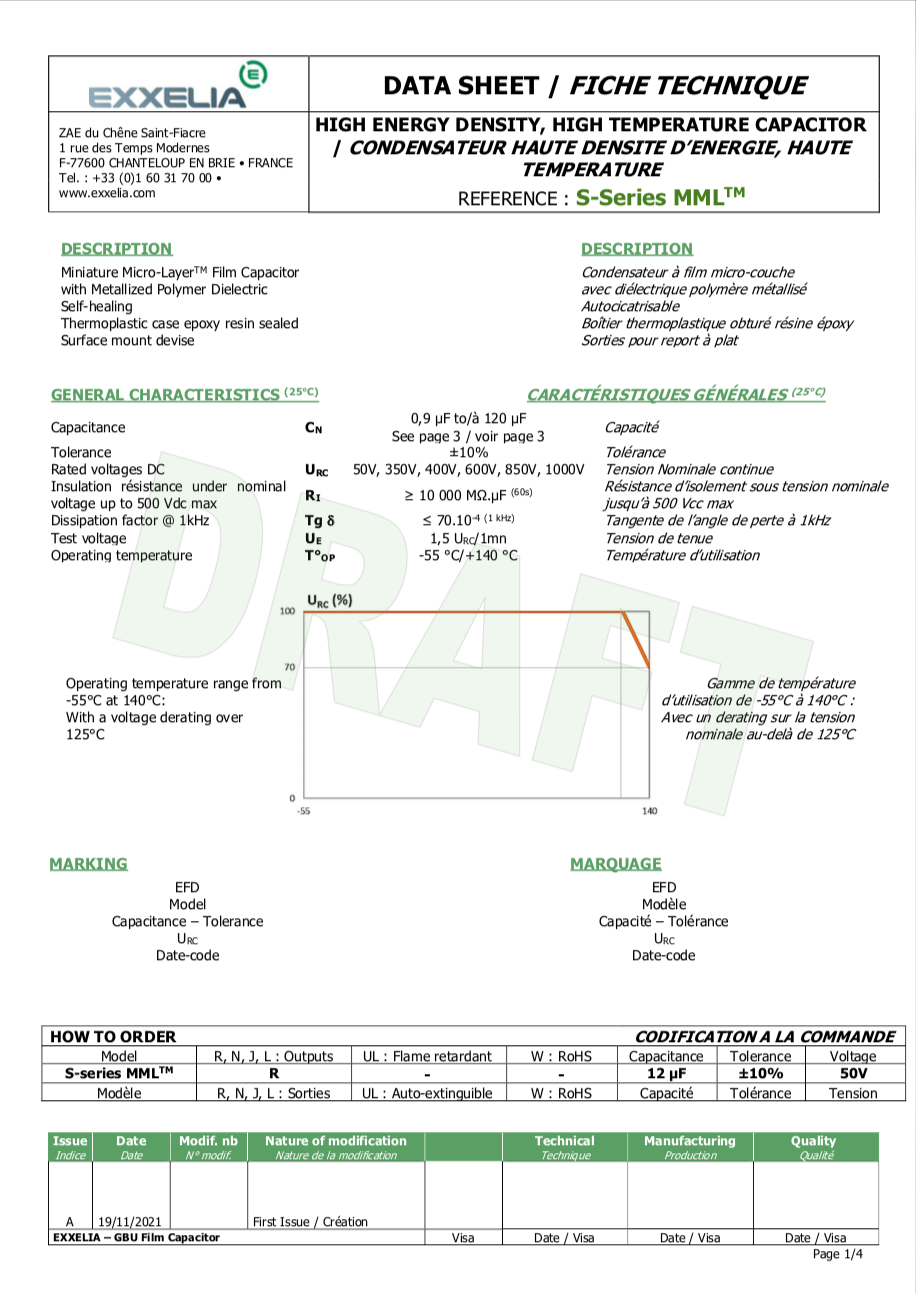

| MML 50µF +/- 10% 450VDC MML R1 - S-Series - | 50µF | - | ±10% | - | - | Non ROHS | 450 |

| MML 50µF +/- 10% 450VDC MML R2 - S-Series - | 50µF | - | ±10% | - | - | Non ROHS | 450 |

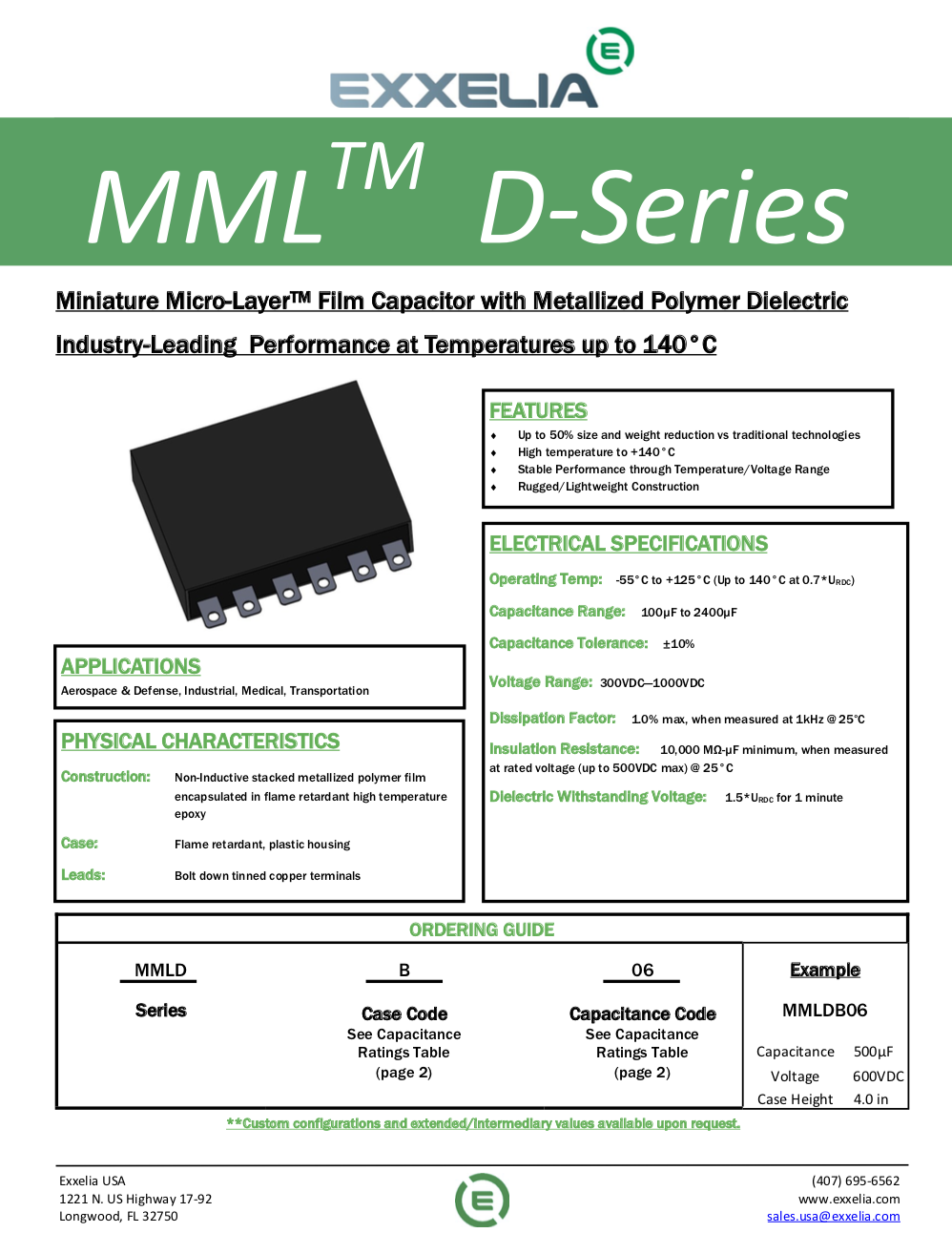

| MML D B04 - 1000µF 450 V - - | 1000µF | - | - | - | - | Non ROHS | 450V |

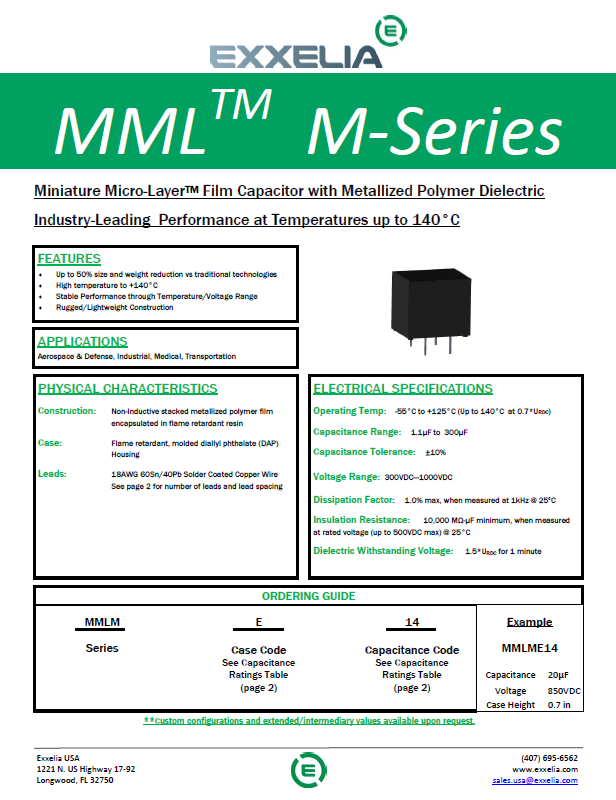

| MML? M-series - 100µF ±10% - 100 VCC - | 100µF | - | ±10% | - | - | Non ROHS | 100 |

| MML? M-series - 12µF ±10% - 450 VCC - | 12µF | - | ±10% | - | - | Non ROHS | 450 |

| MML? M-series - 18µF ±10% - 450 VCC - | 18µF | - | ±10% | - | - | Non ROHS | 450 |

| MML? MB15 12µF ±10% 850 VCC - M-Serie - | 12µF | - | ±10% | - | - | Non ROHS | 850 |

| MML? ME07 90µF ±10% 450 VCC - - | 90µF | - | ±10% | - | - | Non ROHS | 450 |

| MML? S - 120µF ±10% - 100 VCC - | 120µF | - | ±10% | - | - | Non ROHS | 100 |

| MML? S-series - M - 2.4µF ±10% - 1000 VCC - | 2.4µF | - | ±10% | - | - | Non ROHS | 1000 |

| MML? S-series - M ? 200µF ±10% - 50 VCC - | 200µF | - | ±10% | - | - | Non ROHS | 50 |

| MML? S-series - M ? 245µF ±10% - 50 VCC - | 245µF | - | ±10% | - | - | Non ROHS | 50 |

| MML? S-series - M ? 45µF ±10% - 50 VCC - | 45µF | - | ±10% | - | - | Non ROHS | 50 |

Compliance and certifications

ESA

MIL

Would you like to ajust a little something?

Customize it

4related document(s)

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact