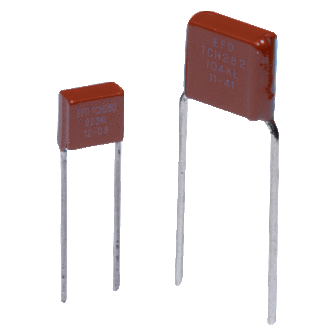

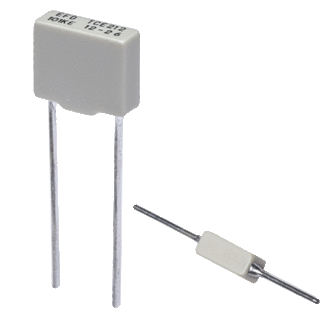

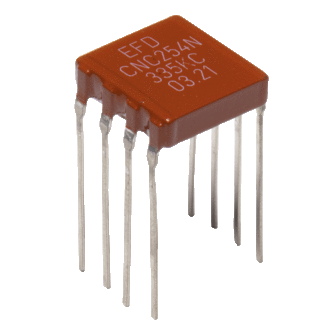

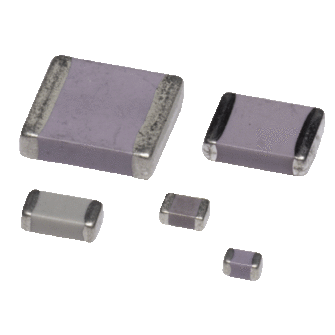

Typical applications :

- Filtering

- Decoupling

The below Part Numbers reflect our high runners only.

Please contact us if you can't find your specifications.

Compliance and certifications

CECC

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact