Exxelia Micropen’s proprietary printing technology enables product designers to bring forth their groundbreaking ideas or explore new possibilities that they once thought out of reach. Designers can DREAM BIGGER and DESIGN BETTER.

Our Micropen printing process has pioneered additive printing from its early days.

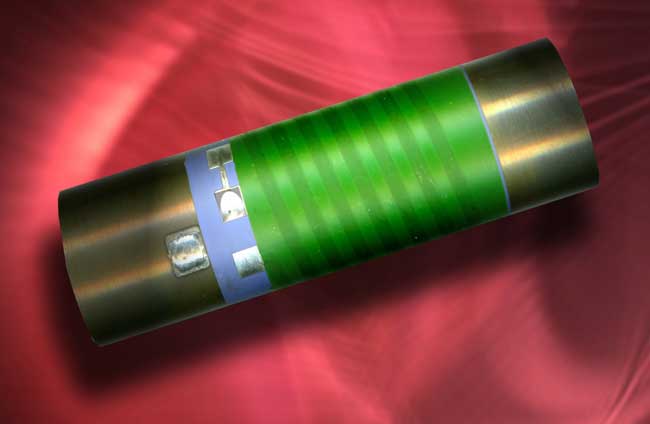

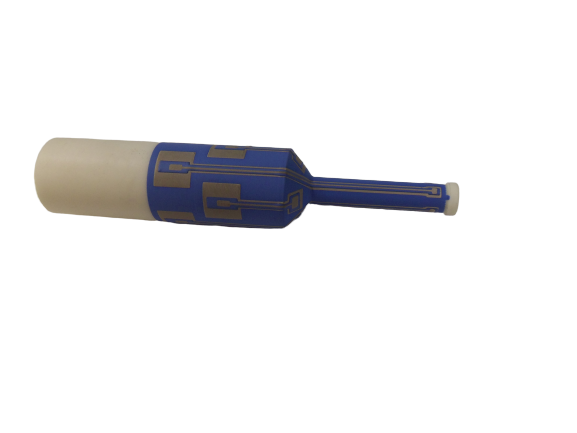

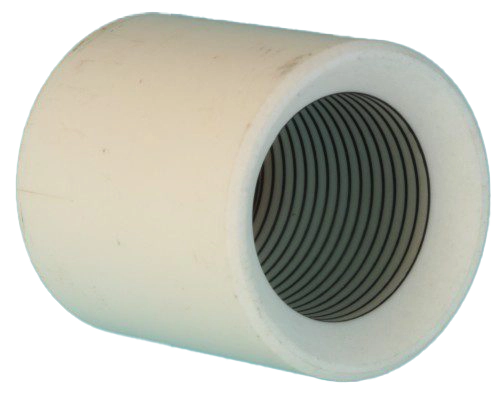

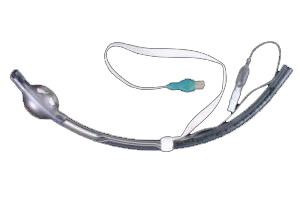

We take a substrate, any substrate, and print electronically conductive patterns, transforming the substrate into a critically important component that can sense, heat, detect, ablate or cauterize. Our technology is the key to making materials more functional, more reliable and more customized.

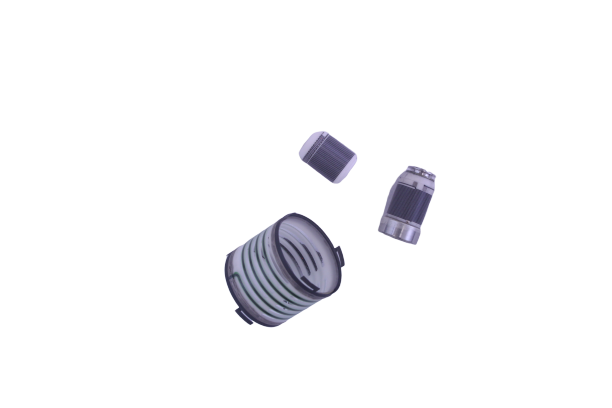

In today’s 3-D printing world, our technology turns static into smart by printing on virtually any 3-D ceramic, metal or polymeric substrate.

Compliance and certifications

Would you like to ajust a little something?

Customize it