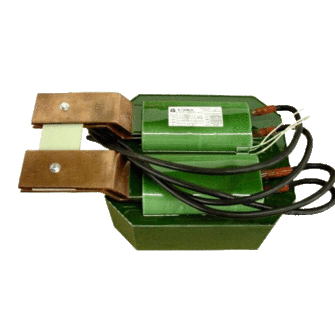

Anodized Aluminium Foil Technologies

Custom example

Low Power

- Anodized aluminium foil winding

- Cold Press Welding

- Vacuum and Pressure Impregnation from 10 mbar up to 5 bar

- No need for insulator, dielectric isolation between turns, up to 100 V

- High Electrical Insulation

- Mechanical strength

- Varnish withstanding up to 200°C

-

Operating Temp

0°C ~ 200°C

-

Accuracy

Standard

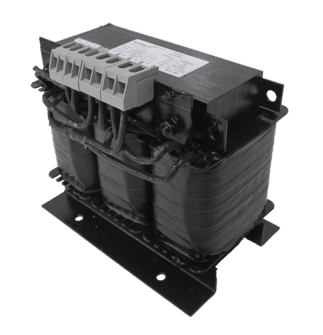

Design and manufacture of:

- Interphase Inductance and twelve pulse transformers

- Filtering chokes up to 400 A

- Active or Passive Power Factor Correction chokes

- Power Transformers up to several kW for standard SMPS and specific architectures.

Compliance and certifications

Custom Qualification Plan

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact