- Dual embedded transformer 2x125kVA

- Primary 550-900V, secondary 330-540V

- Pulsed air flow

- Weight 190 Kg

- 1132 x 348 x 500 mm

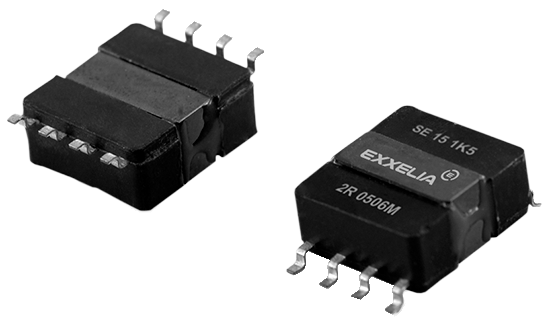

- Embedded

-

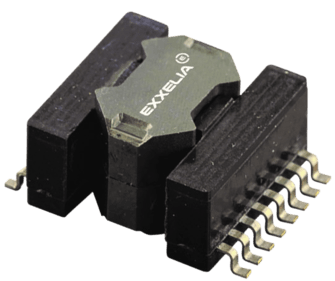

Mounting

Free (In-Line)

-

Frequency

4000Hz

-

Power

125kW

Compliance and certifications

Custom Qualification Plan

Would you like to ajust a little something?

Customize it

1document

Frequently Asked Questions

Find answers to the most frequently asked questions about our products and services.

Still have questions ?

Can’t find the answer you’re looking for ? Please contact with our customer service.

Contact