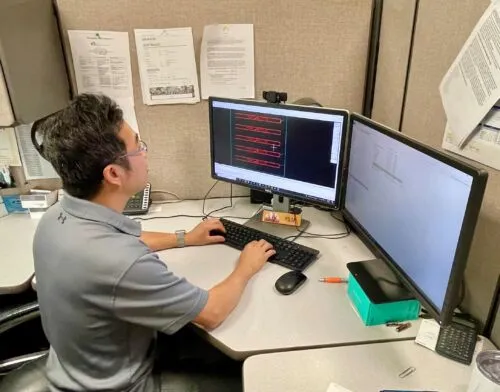

Design

Design it with Micropen

Let the experts at Exxelia Micropen help you with your prototype development, fabrication and concept optimization of components and finished devices for all market segments: Medical Devices, Test & Measurement, and Defense, Military and Space.

Innovation

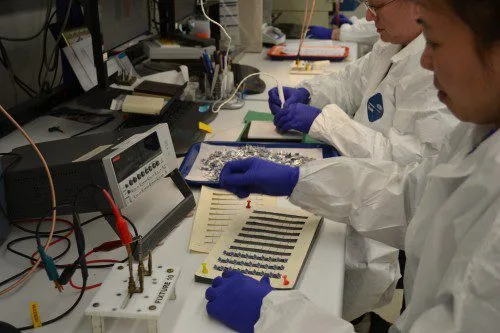

Exxelia Micropen & Ohmcraft specialize in design, engineering and manufacturing of complex products. Through the ability to dispense many different materials and print on a variety of surfaces, the Micropen technology can be tailored to many different, unique, and challenging applications.

Material Formulation

Exxelia Micropen uses off the shelf materials whenever possible to provide the quickest, least expensive path to a solution. With over 30 years of experience with the products of all the major ink and substrate manufacturers. For industry-wide applications that do not have a good off the shelf solution we have developed our own in-house material formulation capability.

Inks: Any liquid material is a candidate for Exxelia Micropen printing. Generally, applications call for flowable materials that range in viscosity from 5 to 500,000 centipoise (cP). A wide variety of printing inks have been identified or developed and optimized for both low temperature, flexible, flat and 3D applications, as well as high temperature ceramics, steels and other materials.

- Conductors.

- Insulators.

- Visualization.

- Specialty Inks.

Consult our Substrates & Inks list.

From the Basic ...

Only Exxelia Micropen has the material science expertise, design engineering expertise and proven success to create the next generation of metallized ceramics.

- Flat Plate Printing: Exxelia Micropen can accommodate writing on flat substrates up to 24” x 24” with available systems.

- Axial Printing: Exxelia Micropen routinely processes tubes and rods from 30 mil (0.030”) diameter up to 6 inch diameter.

- Inside Printing: Exxelia Micropen has the most advanced precision equipment enabling printing even on the inside diameter of a cylinder.

... to the Complex

Only Exxelia Micropen Technologies has precision printing capability for odd topologies, i.e. inside and 3D printing, on any ceramic material, enabling design engineers to push beyond existing boundaries.

- Inside Diameter Writing: Exxelia Micropen has the most advanced precision equipment and experience applying materials on the inside diameter of tubes, ID greater than 0.250.

- 3D Shapes: Exxelia Micropen can print on just about any 3D object. If you supply the substrate, we can offer a solution.

- Multi-layer Applications: Exxelia Micropen has experience with integrating multiple materials in a multilayer circuit, interweaving conductive, resistive, and dielectric materials to meet dimensional and performance specifications.

To Turn-Key Solutions

Only Exxelia Micropen Technologies is able to offer end-to-end design engineering, product development and fabrication, manufacturing and production for advanced metallized ceramic initiatives.

- Ceramic Substrates: CoorsTek, CeramTEC, EnRG, etc.

- Inks: Heraeus, Dupont, Ferro, Creative Materials (CMI) etc.

- Novel Materials and Applications: From substrates of standard ceramic and AlN, to inks of Silver, Gold and Platinum, Exxelia Micropen can work with our strategic partners to find your custom solutions.