Slip Rings

|

Name

|

Download

|

Diameter (Outside Diameter)

|

Description

|

Type of signals

|

|---|---|---|---|---|

| Industrial Slip Rings | - | Long life-time | Power and Data | |

| High Temperature / High Pressure | - | HPHT | Power and Data | |

| Compact Dimension | 20mm | Compact | Power and Data | |

| Medium Dimension | 100mm | Medium size | Power and Data | |

| High RPM Slip rings | - | High RPM | Power and Data | |

| Hollow Shaft Slip rings | - | Hollow shaft | Power and Data | |

| Small dimension | 50mm | Slip rings | Power and high-rate data transfer |

Slip Rings

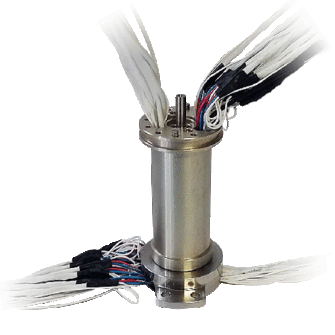

Slip rings and Rotary joints enable signals and/or power to be transmitted from a fixed part (stator) to a mobile part (rotor).

Explore Exxelia’s premium selection of Slip Rings. Designed for seamless performance and reliability in harsh environments, our innovative solutions are made to cater to diverse industrial needs and are built to meet your specific requirements.

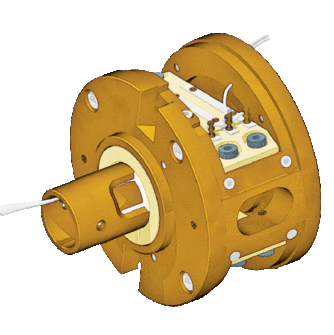

Power slip rings are devices that allow the transmission of electrical power and signals from a stationary to a rotating structure. They are commonly used in rotating machinery and equipment, such as wind turbines, industrial robots, and rotating sensors. The slip rings enable the continuous transfer of power and data between stationary and rotating parts, ensuring seamless operation without the need for tangled cables.

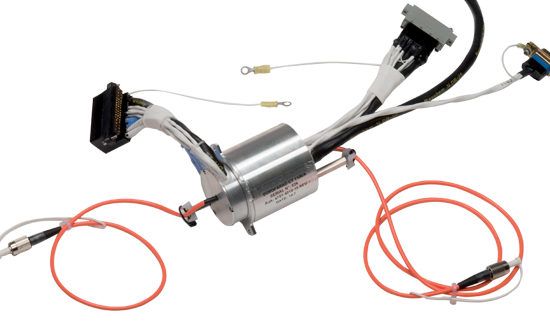

Pancake slip ring is a type of electrical rotary joint that allows the transmission of electrical signals and power between a stationary and a rotating structure. It is called "pancake" due to its flat and compact design. These slip rings are commonly used in applications where space is limited, and they offer a low-profile solution for continuous rotation while maintaining electrical connectivity.

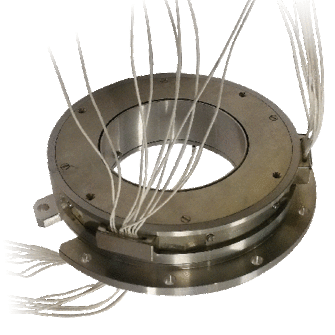

Through Bore / Hollow shaft : Electrical connectors used to transfer power, signals, or data from a stationary part to a rotating part. These slip rings have a hollow shaft in the center, allowing for the passage of other elements such as cables or shafts through the center of the ring. This design is particularly useful in applications where space or size constraints are a consideration, enabling a more compact and efficient transfer of electrical signals in rotating systems.