Discover Exxelia's Smart Magnetic technology: compact, reliable, cost-effective, eco-friendly converters for diverse applications. Explore the benefits today!

The solutions provided by Exxelia's Smart Magnetic project are revolutionizing the field of electrical converters by offering unparalleled performance in terms of power density.

This advance makes it possible to design more compact, lighter converters. However, the advantages of this technology are not limited to these fundamental aspects. In this article, we will explore in detail the multiple functional, economic and environmental benefits offered by Exxelia's Smart Magnetic technology.

Functional advantages for increased reliability:

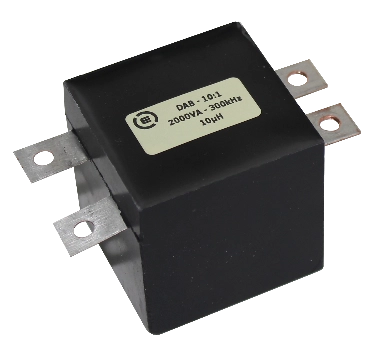

The Smart Magnetics project makes it possible in particular to optimize the Dual Active Bridge topology which requires the combination of a transformer and a choke.

The Dual Active Bridge converter is a technology that is becoming widespread because it allows bidirectional power transmission. This meets the challenges of electrical systems (recovery + supply of energy),

Integrating the Dual Active Bridge (DAB) transformer and choke into a single component has significant functional advantages. Unlike assembling two separate components, using an integrated component eliminates interconnections. The repeatability and reproducibility of the processes guarantee perfect control of the electrical characteristics, and ensure optimum performance of the converter. In addition, this consolidation reduces the number of components required, which improves the reliability of the final product.

Rationalization of the value chain for optimized production costs:

The Smart Magnetic project also contributes to improving the value chain through effective streamlining. By replacing two distinct components with a single component, the management of the components of the circuit is simplified. From the customer's point of view, there is only one product to supply, one product to integrate/assemble in the system. These simplifications result in high added value and increased competitiveness on the market.

Contribution to a more environmentally friendly industry:

By adopting Smart Magnetic solutions, the benefits go beyond simply improving energy efficiency. This innovation also reduces the consumption of raw materials by using less material in the Smart Magnetic component compared to standard formats requiring two separate components. As a result, this technology contributes to the preservation of natural resources. In addition, Smart Magnetic responds to the challenges posed by the electrification of vehicles, whether in air, land or sea transport, by promoting the deployment of solutions that are less dependent on fossil fuels.

Various applications:

The versatility of Smart Magnetic solutions makes it suitable for many applications. For example, it can be used as a bi-directional converter between batteries and circuits, for power applications or even in resonant converter topologies. It is also useful in applications requiring high current and in Multi-output flyback converters. This diverse range of applications testifies to the flexibility of the Smart Magnetic project.

A project ?

Do not hesitate to contact us.