News

Exxelia SVM’s Advanced Multilayer Laminated Busbars for Power Electronics

Exxelia SVM Private Limited is proud to offer a comprehensive range of bus bars tailored to the demanding requirements of power electronics applications. Whether it’s laminated, molded, or insulated bus bars with resin or powder coatings bus bars, each solution is meticulously designed for optimal performance.

Exxelia Unveils New Website

Exxelia has launched its new website, designed to offer an improved user experience.

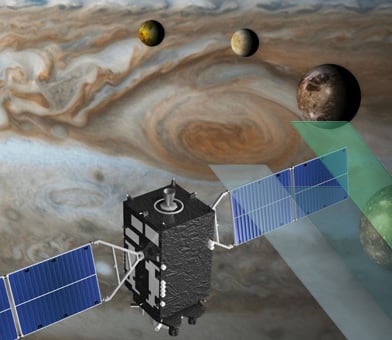

Exxelia Ohmcraft Powers NASA’s Europa Clipper with Custom Resistors for Pioneering Space Mission

Over 20 custom resistors are key to Europa Clipper’s advanced scientific instruments, critical for exploring Jupiter’s moon

Exxelia expands footprint in India with strategic investment in SVM

Enhancing its Magnetics offering for Medical and adding Busbars to its power electronics passive components portfolio.

Discover our range of Exxelia Alcon film capacitors

As the transportation industry advances, the demand for reliable, high-performance electronic components becomes increasingly critical.

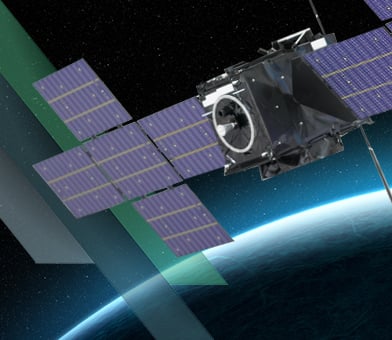

Discover the power of MML™ film Capacitors

With unparalleled energy density and a host of advanced features, these capacitors are revolutionizing design possibilities and performance standards in satellite constellations and beyond.

Exxelia inside eVTOLs

Exxelia's Smart Magnetics initiative introduces a groundbreaking approach to electrical converters, specifically tailored to meet the demanding requirements of eVTOL (Electric Vertical Takeoff and Landing) vehicles.

Smart Magnetics Innovation: Enhancing Next-Generation Resonant and Bidirectional Power Converters

Exxelia introduces groundbreaking innovations in smart magnetics technology, specifically tailored for resonant bidirectional power converters. These advancements are set to redefine efficiency and performance standards across a spectrum of applications.

Exxelia to showcase advanced Microwave Capacitors and Ferrites at IMS Microwave week 2024

At booth 2108, Exxelia will highlight its main RF/Microwave capacitor ranges: Super HiQ & High-Power High-Q CP/CL series

Countering Threats from Transients in Magnetics ; Exxelia to Showcase Innovations at CMSE 2024

Exxelia is pleased to exhibit at CMSE 2024 in Four Points by Sheraton hotel, in Los Angeles, from April 30 to May 2, 2024. Visit our booth B11

100+

years old

Exxelia's oldest company was founded in 1921

3100

employees

NASA

certified

50+

Years

Of combined Micropen processing & materials experience

13

locations

Across 5 countries: France, USA, Morocco, India and Vietnam