Exxelia Micropen

About Micropen

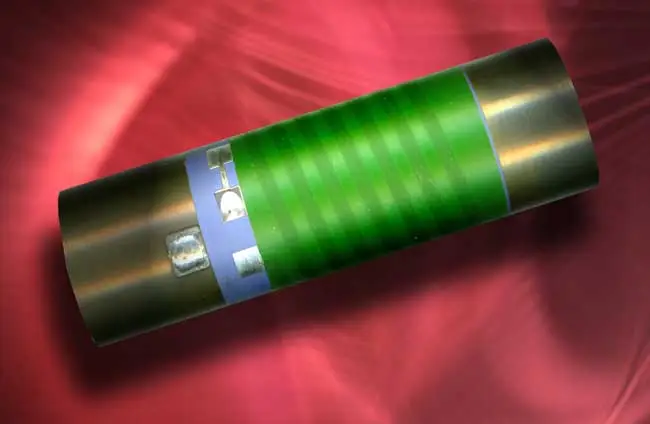

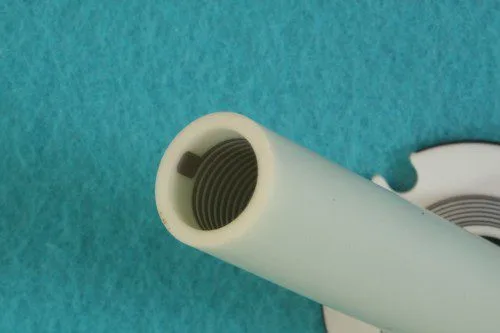

Micropenning, a “direct write” technology, is Exxelia Micropen’s proprietary technique for manufacturing all of its products. This proprietary technique allows for the deposition of a wide range of material compositions with higher fidelity, accuracy, repeatability, and thickness control than can be achieved by other printing techniques. The “Micropenning” process can print lines down to a few mils in width with smoother edges and greater thickness accuracy than screen printing. This provides design engineers with unmatched capability and design options – long, narrow traces without neck downs allow for longer pattern lengths in smaller areas and on irregular surfaces.

Exxelia Micropen’s products can be found in many different market segments from medical device to defense and security.

About Exxelia Micropen

MAIN APPLICATIONS

Custom

designs experts

from minor catalog product adjustment to 100% custom design based on your specifications

40+ years

experience

in electronic printing

3000

customers

spread in more than 50 countries on all continents

30+

Inks & substrates

Used for 3D electronic precise printing

10+

Applications

In medical, aerospace, defense, & industrial devices

Success Stories