Exxelia at Space Tech Expo – Booth #5009

Exxelia is exhibiting at Space Tech Expo 2017 in Pasadena, California. From May 23th to 25th at booth # 5009, Exxelia will be showcasing innovative components dedicated to space applications.

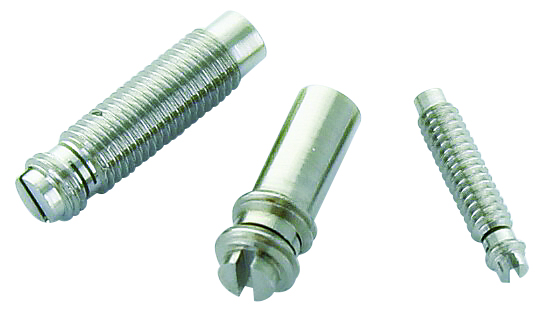

100% invar tuning screws with self-locking system

Invar-36 is a unique Iron-Nickel alloy (64 % Fe / 36 % Ni) sought-after for its very low coefficient of thermal expansion. With 1.1 ppm. K–1 between 0°C and 100°C, Invar-36 is about 17 times more stable than Brass which is the most traditional and common alloy Tuning Elements are made of. The working temperature range in Space is so wide that this property becomes essential for a reliable and stable cavity filter tuning. Self-locking system is a technology commonly used on Tuning Element made of Brass or other soft “easy-to-machine” alloys but is innovative and pretty advanced when applied to hard and tough Invar 36. The design consists of two threaded segments separated by two parallel slots. After cutting both parallel slots, the rotor is compressed in its length in order to create a plastic deformation. Thus, an offset is induced between the two threaded segments which generates a constant tensile stress in the rotor from the moment threaded segments are screwed.

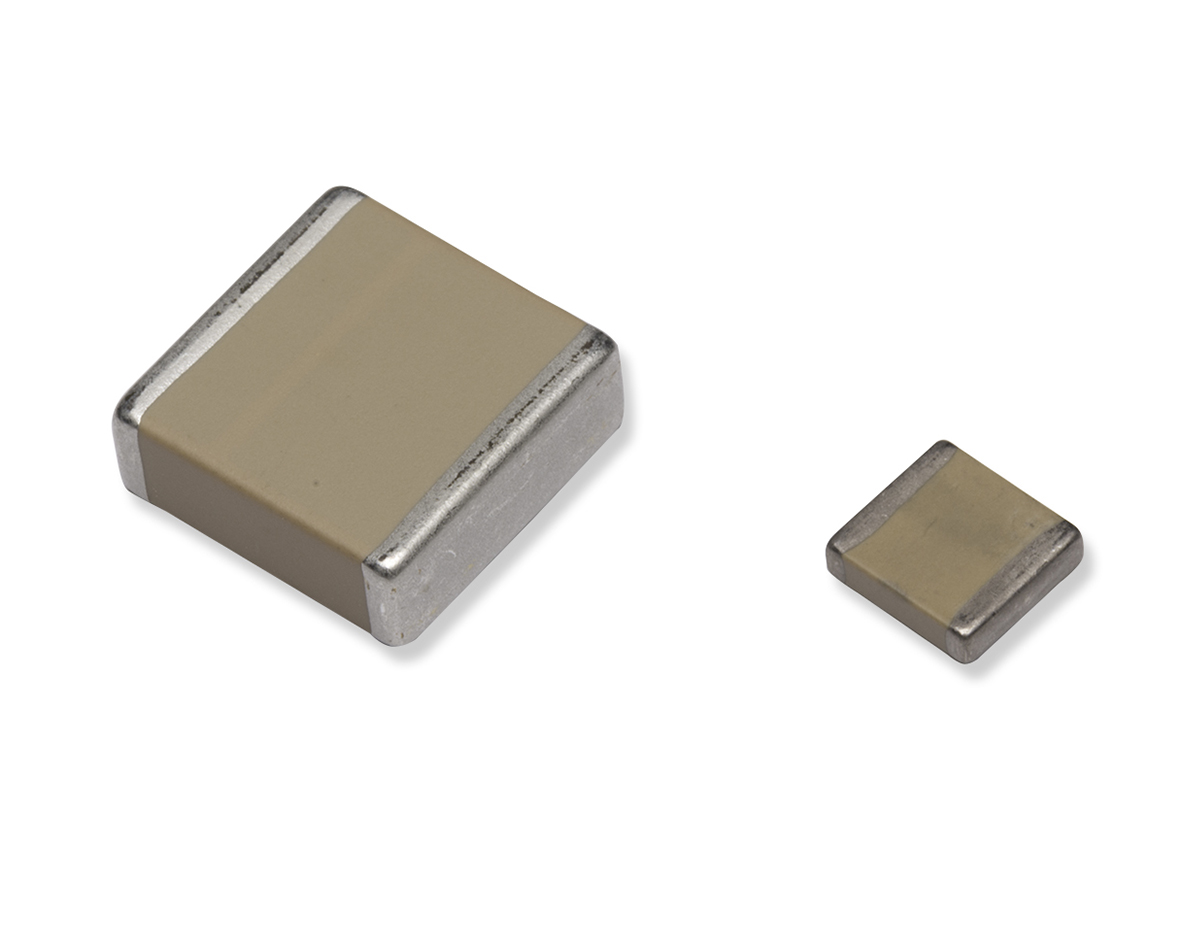

High power and high frequency ceramics with the new C48X dielectric

Range of high voltage ceramic capacitors based on brand new dielectric material C48X, combining most advantages of NPO and X7R dielectrics. Compared to X7R material, C48X dielectric allows to get the same capacitance values under working voltage with the unrivaled advantage of a very low dissipation factor (less than 5.10–4). Besides, it can also withstand very high dV/dt, up to 10kV/μs, which makes it the solution of choice for pulse and fast charge/discharge applications or firing units. Thus capacitors with C48X dielectric appear to be ideally suited for power applications where heat dissipation may be detrimental to performances and reliability.

Range of high voltage ceramic capacitors based on brand new dielectric material C48X, combining most advantages of NPO and X7R dielectrics. Compared to X7R material, C48X dielectric allows to get the same capacitance values under working voltage with the unrivaled advantage of a very low dissipation factor (less than 5.10–4). Besides, it can also withstand very high dV/dt, up to 10kV/μs, which makes it the solution of choice for pulse and fast charge/discharge applications or firing units. Thus capacitors with C48X dielectric appear to be ideally suited for power applications where heat dissipation may be detrimental to performances and reliability.

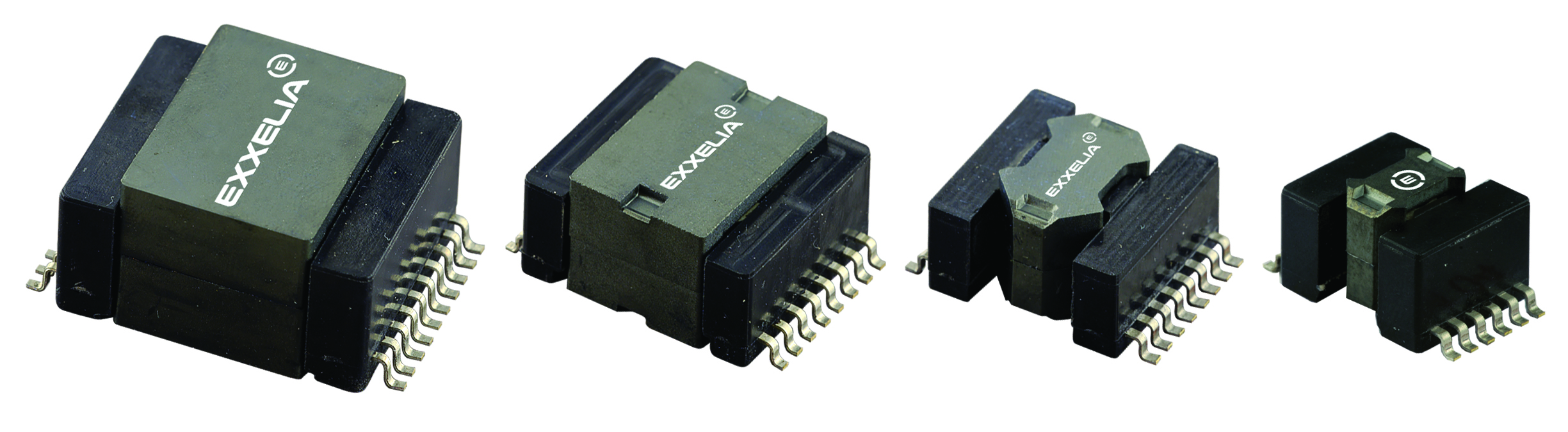

Magnetic components based on adaptive CCM technology

Exxelia designed CCM technology to respond to the growing interest of electronic engineers for inductors and transformers with multiple outputs, high power density and reduced footprint.

Exxelia designed CCM technology to respond to the growing interest of electronic engineers for inductors and transformers with multiple outputs, high power density and reduced footprint.

Qualified for aeronautic and space applications, the CCM product line features terrific robustness. The CCM technology adapts to most every need, even the harshest environments, including VIGON® resistance. The series offers five different sizes, allowing optimized component design in a pick-and-place surface mount (SMD) package. Through-hole (TH) packages are also available upon request. CCM transformers and inductors can operate over a wide temperature range with a minimal temperature of -55° C. The standard thermal grade of the technology is 140° C. The epoxy molding protecting the winding ensures a lower temperature gradient and a better heat dissipation. Each unit is thoroughly tested with a dielectric withstanding strength of 1,500 VAC.