Catalog Ohmcraft Resistors

Ohmcraft Resistors High Voltage, Thick Film

Catalogs & brochures

Catalogs & brochures

RF Models

RF Models

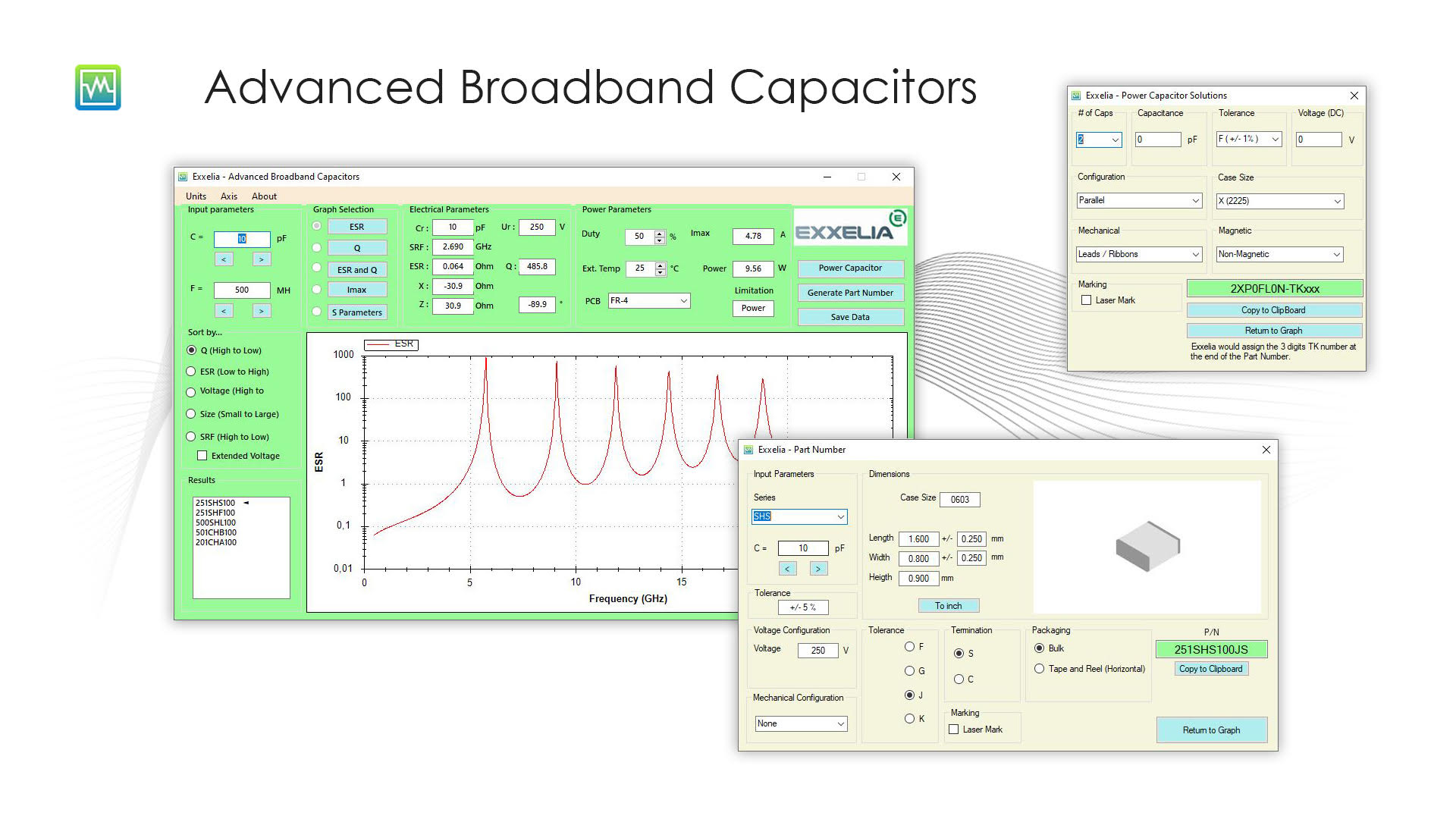

The Exxelia ABC software provides electrical parameters (ESR, Q-Factor, Resonance frequency, S-parameters etc.) for all Exxelia High-Q capacitor sizes ranging from 0402 to 1111. Exxelia ABC is a software capable of analyzing the frequency behavior of capacitors. It is easy to use, light, modular and does not require an internet connection to operate.

MODELITHICS, INC. is a leading-edge technology company that provides highly accurate, scalable measurement-based simulation models for all types of RF and microwave devices, as well as comprehensive RF and microwave precision measurement services. Modelithics models are compatible with multiple popular EDA tools. The models capture parasitic effects of RF and microwave components, and offer scalable design parameters, such as substrate scaling, pad scaling and part value scaling, plus adjustable active device model parameters such as bias and temperature. The advanced features provide for powerful design analysis, leading to significantly increased simulation accuracy and first pass design success. Through the Modelithics Vendor Partner Program (MVP), Modelithics collaborates with RF component and semiconductor device manufacturers by developing these advanced models for their components. Exxelia High-Q on Modelithics website : https://www.modelithics.com/mvp/exxelia

MODELITHICS, INC. is a leading-edge technology company that provides highly accurate, scalable measurement-based simulation models for all types of RF and microwave devices, as well as comprehensive RF and microwave precision measurement services. Modelithics models are compatible with multiple popular EDA tools. The models capture parasitic effects of RF and microwave components, and offer scalable design parameters, such as substrate scaling, pad scaling and part value scaling, plus adjustable active device model parameters such as bias and temperature. The advanced features provide for powerful design analysis, leading to significantly increased simulation accuracy and first pass design success. Through the Modelithics Vendor Partner Program (MVP), Modelithics collaborates with RF component and semiconductor device manufacturers by developing these advanced models for their components. Exxelia High-Q on Modelithics website : https://www.modelithics.com/mvp/exxelia

Custom Designs

Custom Designs

FAQ

FAQ

Two major benefits of film capacitors comes from the fact that they have low equivalent series resistance and low self inductance. Due to these properties, they can be designed to withstand voltages in the kilovolts. Power film capacitors take these benefits even farther and can withstand reactive power over 200 volt amperes in charge. These types of benefits make them very attractive overall to a wide variety of different types of industries all over the world. Constructions costs can be slashed even farther through the use of special materials.

Our film capacitor are very specific types of capacitor that uses a thin plastic film as a dielectric element in the configuration. The thin plastic film is made using a technologically advanced film drawing process. Depending on how the capacitor needs to operate when it is finally configured, the thin material may be either left untreated or metalized after the manufacturing process. Once the film material has been added, electrodes are placed into the assembly, which is mounted into a case that is designed to protect the capacitor from a wide variety of different environmental factors. Due to the fact that they are incredibly stable, do not cost a significant amount of money to manufacture and have a low rate of inductance, they are being used in many different types of applications. Buyer beware, there are many different types of capacitors on the Internet that qualify as film capacitors that just change the type of material being used as the dielectric. Our high-quality polymer film capacitors, plastic film capacitors, power film capacitors and more are readily available to meet your needs. The specific type of material that will be used during the creation of the capacitor will vary depending on what the device will end up being used for. Let us know how we can help in meeting your needs and exceeding your expectations.

Plastics come in such a wide range that they can cater to most of our technical needs. They can be used in high-temperature applications (Teflon), power (polypropylene), energy conversion (polyester), and for functions requiring high stability (polycarbonate). The product range extends from capacitor outputs for implementation on printed circuits, to metal housings with terminal output for power capacitors in wired circuits. Surface mounted devices (SMD) and fi lm capacitors withstanding high temperatures are also manufactured.

Film capacitors are used in a wide variety of different industry, including with military technology and applications as well as the aerospace industry. This is mainly due to the fact that they have high long term stability, can be produced relatively cheaply and are heat resistant. One of the main characteristics of our film capacitor comes from the fact that they are not polarized. Due to this design element, they are available for use in both AC power and signal applications. They are also designed to have high precision capacitance values, which means that they can retain their value for a much longer period of time than capacitors of other types. The aging process of these types of capacitors is generally much slower than it would be if a different type of material were being used during construction.

Exxelia’s film capacitor product lines include a wide array of custom designs using state of the art technologies combined with the latest developments in dielectric films (including polyester, polypropylene, PPS, and teflon). Kraft/paper, foil capacitor, and metallized film capacitor products are available. This allows Exxelia to provide high temperature capability; high voltage ratings; precision capacitors with ± ¼% tolerances, and exceptional performance in harsh environments. Military film capacitors are tested and qualified to military standards, with more than 30 military qualified products. Film capacitors are exceptional for pulse/storage, DC link, energy discharge, and custom applications.

A wide selection of packaging designs are available such as film-wrapped, pre-molded epoxy cases, and hermetically sealed metal cases. Exxelia continues to research and develop film caps with new methods in capacitor manufacturing to provide durable designs and packaging schemes for special environmental use.

This natural mineral insulator has outstanding dielectric properties that are ideal for long-life high-stability capacitors with low loss at all frequencies, and high dielectric strength. This type of capacitor is used particularly for high frequency and delay line applications, oscillating circuits, emission devices and calibrators.

Mica dielectric capacitor technology allows for several custom design applications including: High voltage capacitors (up to 50 kV) • High temperature capacitors (up to 250°C) • Precision capacitors (up to ± 0.1%) • High stability capacitors (– 20 + 30 ppm/°C) • High frequency capacitors ( up to several GHz). The majority of these capacitors are manufactured to comply to specifications NF-C-83120;MIL-C-5 and MIL-PRF-39001 standards.

Mica capacitors are noted for the following characteristics:

Silver mica capacitors provide superior stability and low loss when used in RF power circuits that require low pico farad (pF) and nano farad (nF) ranges. Older silver mica capacitors were manufactured in layers of mica and silver, but the layering allowed room for air gaps that reduced the stability and could also create stress fractures in the assembly.

Modern manufacturing uses silver plated to mica layers, eliminating the gaps. When the desired number of layers is obtained, the assembly is coated in an epoxy or ceramic resin. The coating reduces fracturing of the layers and seals the assembly from moisture and particles that could interfere with the capacitance value.

Mica capacitors are useful in circuits for ripple filtering and are often found in time constant, coupling or resonance circuits. In addition to radio circuits, they are used in TV transmitters and Cable TV amplification circuits. Mica is also a superior choice in high-voltage inversion and power conversion for energy absorbing snubber applications with capacitances of up to 10 nF.

Standard silver mica capacitors are normally designed to handle voltages from 100 to 1000 volts. High-voltage RF transmitter applications can call for higher tolerances. Mica capacitors are available for voltages up to 20kV.

Our expert engineering team can create the mica capacitor with the characteristics you require. Send us your drawing or file and we will work with you to manufacture the correct size, lead style and capacitance you desire.

These capacitors offer a very high charge per unit of volume, a long lifetime and a high reliability. They are used in consumer goods and more specialized niches including space vehicles, aircraft electronics, weapons and rail transport. Exxelia develops both solid and wet tantalum capacitors.

A tantalum capacitor is a specific type of electrolytic capacitor. It is made from a metal called tantalum, which is where it gets its name. Tantalum acts as an anode. The capacitor itself is covered in a thin layer of oxide, which allows it to act as the dielectric. It is surrounded by a conductive cathode. One of the major benefits of tantalum capacitors is that their design allows for a very thin layer of dielectric, which allows for higher capacitance than other types of capacitors made from different types of materials. These types of capacitors are generally polarized, which means that in practice they can only be connected to a direct current power supply that has been designed while observing the appropriate terminal polarity. They have excellent stability over time and superior frequency characteristics when compared to different types of similar capacitors that are made from different materials.

A key characteristic of the tantalum capacitor with Mn02 cathode is its failure mode, which could be potentially dangerous under the right conditions. In the event of a voltage spike, if the circumstances align just right it could start a chemical reaction would could produce heat, smoke and even flame. The potential for dangerous situations is very limited due to the presence of some types of fail safes and other precautions that are taken during the construction of tantalum capacitors.

Tha being said, the use of Tantalum capacitors with polymer cathode is the perfect solution to completly cross this failure mode off your list. Polymer is free from O2, which makes ignition impossible.

Aluminum electrolytic capacitors, also commonly known as just electrolytic capacitors, are a unique type of configuration that uses an electrolyte to achieve a capacitance that is much larger than other types of these devices. The electrolyte in question is usually either a gel or a liquid that itself contains a very high concentration of polarized ions. Polarization indicates that the voltage on the positive terminal is always larger than the similar voltage on the negative terminal of the capacitor.

One of the major benefits of these types of aluminum electrolytic capacitors is the aforementioned large capacitance. They do, however, have a number of disadvantages when compared to other types of capacitors. Aluminum electrolytic capacitors have a large leakage current when compared to capacitors of other types. Additional disadvantages include a limited lifetime, value tolerances and an equivalent resistance series.

For safety purposes, these types of capacitors need to be forward biased in their configuration. This is mainly due to the characteristics of the electrolyte that has been used in their construction. The positive terminal always needs to have a larger amount of voltage than that of the negative terminal. If the situation were reversed and the negative terminal suddenly had a higher voltage than the positive terminal (which is also referred to as reversing the voltage polarity), the aluminum material that is used as the dielectric could short circuit and become damaged. It could also overheat, which could cause a substantial leak. The capacitor could also vaporize, which could cause the entire enclosure to burst under the right circumstances. It is important to note, however, that this phenomenon is very rare.

Excellent temperature resistance, high volume/capacitance ratio, electrical properties and reliability make Exxelia's ceramic capacitors ideal for a wide range of fields of application including medical implants, aircraft flight controls, switched-mode power supply in harsh environments, core samplers for petroleum exploration, and space vehicles. Exxelia also offers Hyper Frequency ceramic capacitors with optimized size and very low ESR. These HiQ capacitors offer excellent performance levels for RF applications requiring functional reliability. Typically these applications include civil and military telecommunications (cellular base station equipment, wireless broadband service, Point to-Point or Multipoint radios, radio broadcasting equipment), and MRI coils.

Ceramic chips are created with binders and solvents added to a specified ceramic powder. The slurry created is dried, forming a sheet or tape of ceramic material. Metal powder is mixed with solvents and additional ceramic material to create a liquid electrode. The liquid is then printed onto the ceramic layer. Layers of the ceramic sheets are stacked and laminated to form a solid structure.

The solid structure is cut into the desired size. Once cutting is complete, the assembly must be kiln fired. The temperature used in the firing process is critical in determining the capacitor’s characteristics. The process is similar for disc and chip styles. Disc capacitors use long leads to mount through circuit boards. Chips use surface mount technology.

Electrodes used in ceramic capacitors come under the categories of precious metals or base metals. Silver is used for manufacturing capacitors for higher voltage ratings, 500V and above. Copper and nickel are used for applications under 500 V.

Exxelia can provide you with chip style ceramic capacitors that handle up to 1kV in operating ranges of -55° C to 125° C. Standard tolerances include +/- 5, +/- 10 and +/- 20 percent. For stringent applications, tolerances can be as low as +/- 0.25 pF.

Our multilayer ceramic capacitor (MLCC) is a chip capacitor manufactured with layers of ceramic material and metal. The alternating layers can be built up to the desired capacitance range. The dielectric thickness determines the voltage rating. The capacitance is determined by multiplying the number of layers by the amount of active area and then the dielectric constant for the material. This number is then divided by the dielectric thickness. The active area is the overlap between the electrodes.

A capacitor with a thicker dielectric layer handles higher voltages than one with a thinner layer. Inversely, the thinner dielectric will have a higher capacitance rating. The MLCC design provides a significant space-saving advantage over other capacitor styles.

A Class 1 ceramic capacitor is the best choice for applications that demand low losses and high stability. This style provides a reliable capacitance within the designated range of frequency, temperature and voltage. Class 2 series offer higher capacitance, but have wider fluctuations. The thermal stability varies by +/- 15 percent; these should be used in applications that do not require a continual exact capacitance. Exxelia uses NPO and P100 as Class 1 dielectrics ; and BX, 2C1 and X7R as Class 2 dielectrics.

Class 1 feedthrough capacitors offer high frequency noise reduction, and are excellent for use in microwave transmission, medical applications and DC supply and signal lines. Feedthrough design uses an axial-style lead for connections.

Modelithics passive and active, measurement-based simulation models integrate seamlessly with the latest electronic design automation (EDA) simulation tools, including Keysight Technologies’ Advanced Design System (ADS), NI AWR Design Environment/Microwave Office™, Keysight Technologies’ Genesys, ANSYS® HFSS™ and Sonnet® .

Modelithics passive and active, measurement-based simulation models integrate seamlessly with the latest electronic design automation (EDA) simulation tools, including Keysight Technologies’ Advanced Design System (ADS), NI AWR Design Environment/Microwave Office™, Keysight Technologies’ Genesys, ANSYS® HFSS™ and Sonnet® .

Modelithics high accuracy models capture parasitic effects and reliably predict how component performance changes with various scalable input parameters over a specified frequency range. The scaling and optimization features provide advanced analysis capability and allow RF circuit designers to quickly meet design goals. Visit the products page for more information on the advantages of Modelithics models. Our goal is to help you achieve first pass design success!

Find Exxelia product on Modelithics here.

Our high voltage capacitors are specifically designed to be able to withstand a larger amount of electrical charge than other types of capacitors can offer. They use two main mechanisms to store the energy that is being transmitted, which is contrary to the conventional dielectric method that is used with other types of capacitors. The first main method used to store electricity is called double layer capacitance, while the second is called pseudo capacitance. These methods are electrostatic and electrochemical in origin, respectively, which allows high voltage capacitors to combine the energy storing methods of normal capacitors with the methods used during the operation of a normal battery.

High voltage capacitors can be made from a few different types of material. High voltage ceramics capacitors and metalized polyester film capacitors are just two of the main types. They are notable for a few different characteristics:

Charge time – Even though different types of technology are at work with regards to the way high voltage types of capacitors operate, they still have both discharge and charge times that are very comparable to those of regular capacitors. These charge times are possible due to the low internal resistance in the materials at play.

Specific power – Another main characteristic that sets these types of capacitors apart is specific power, which means that they have a specific power of up to ten times larger than regular batteries.

Cycle life and safety – High voltage capacitors are much safer than traditional capacitors and batteries, even when they’re being mistreated. A traditional battery, for example, has been known to fully explode if it is short circuited, experiences excessive heat or is involved in other types of situations.

Unlimited charging – High voltage capacitors can also be charged and discharged a virtually unlimited number of times. Traditional capacitors and batteries can only be charged around 500 times before they start to lose some of their original power.

Because of these reasons, high voltage capacitors made from all types of materials are very useful during situations where energy needs to be stored and released on a frequent basis.

Exxelia has a long history providing high temperature capacitors to various industries. Several dielectrics, such as plastic (PTFE; PI; & PEI), reconstituted mica, aluminum electrolytic, tantalum and ceramic are used for manufacturing high temperature capacitors. Many are impregnated with solid thermo-setting resins such as epoxy, polyester or silicone.

These technologies provide very high stability of mechanical and electrical characteristics with temperature capabilities of -55°C to as high as +230°C, depending on the dielectric technology, and some do not require voltage de-rating. Rated voltages span from 30 VDC to as high as 60,000 VDC with capacitance ranges 100pF to 30µF.

High temperature capacitors have a wide variety of different uses depending on the industry. In avionics, for example, they are required to fulfill a large number of different tasks. The operating temperature of avionics equipment can vary significantly depending on their location, ranging from anywhere between 130 degrees Fahrenheit to 390 degrees or more. As a result, these types of capacitors are used to power electronics like motor controls, landing systems, fuel pumps and more. The high temperature capacitors will help make sure that these types of equipment can both withstand the extensive heat cycling and go through a long operational life.

When you’re performing any type of application, it is always important to consider the type of capacitor that you choose to use very carefully. High temperature tantalum capacitors and high temperature ceramic capacitors are just two of the main types that are available to work reliably at high temperatures where other types of solutions might fail.

High temperature tantalum products are designed for use in situations where you might be using down-hoe drilling equipment, for example. They are ideal for this type of input and output due to their capabilities for high ripple current. They have also been known to have the additional benefit of current values that offer lower leakage compared to other types of capacitor technologies.

High temperature ceramic capacitors and high temperature mica capacitors are often used in situations that require a higher voltage or a higher power than normal. Because of the ways in which they are built, they can offer low ESR and excellent inrush current and ripple capabilities that other types of capacitors cannot. The only downside is that they tend to be physically larger than other types of capacitors.

The automotive industry is another area where high temperature capacitors are required. The temperature conditions can vary dramatically depending on what area of a car you’re talking about. The brake systems, the engine and the transmission are often the most temperature intensive areas.

The main goal of high temperature capacitors is to allow for stable performance of electrical equipment at high temperatures. They are also involved heavily in applications that require a high level of reliability. Though there are a wide variety of different capacitors and types of technologies that are available depending on the needs of the situation, only a few are available that can operate in a reliable way once temperatures become elevated. High temperature capacitors made out of materials like ceramic or tantalum are usually employed when an application begins to operate at a temperature near or above 350 degrees Fahrenheit.

If you need any additional information, check out the list of Exxelia Sales Representatives that are in operation across the world. You can also view the list of our Distributors to find out more information about the distributors who are operating nearest to your location.

Please do not hesitate to contact us if you have any additional questions regarding our company or the products and services that we provide. Using your web browser you can contact us in a number of different ways, including to request a quote, send us a file or drawing or send us an email. We look forward to hearing from you.

It is built as a single element: a capacitor from line to ground, with a through wire connecting the input to output. It has attenuation characteristics that increase at 20 dB per decade from its cutoff frequency to at least that frequency where it exhibits a minimum attenuation of 60 dB. It maintains this attenuation at higher frequencies. A feedthrough capacitor filter is usually the best choice for filtering lines that exhibit very high impedance. A feedthrough capacitor, in this website, will be referred to as a C filter.

C-Only Filters are the choice for very high impedance lines.

Two elements: a feedthrough capacitor from line to ground, and an inductor connected in series with it between the input and output terminals.

The capacitive element can be placed on either the line or load side of the filter, making it either a capacitive or inductive input. Its attenuation increases at 40 dB per decade from its cutoff frequency to at least that frequency where it exhibits a minimum attenuation of 70 dB. It maintains this level at higher frequencies. They are commonly referred to as L filters:

The inductive element is best placed so that it faces the lower impedance.

A three-section filter consisting of two feedthrough capacitors to ground with a series inductor between them. The Pi filter is usually symmetrical, as are all the Pi filters in this catalog, but circumstances sometimes warrant use of asymmetrical Pi circuits. A Pi filter has attenuation characteristics that increase at 60 dB per decade from its cutoff frequency to at least that frequency where it exhibits a minimum attenuation of 80 dB. It maintains this level at higher frequencies.

Pi-Only Filters are the choice when high levels of attenuation are required and both the input & output impedances are similar.

A three-section filter consisting of two series-connected inductors between the input and output terminals, with a feedthrough capacitor between them from line to ground. The T filter is usually symmetrical (identical inductive elements), but circumstances sometimes warrant use of asymmetrical circuits. A T filter has attenuation characteristics that increase at 60 dB from its cutoff frequency to at least that frequency where it exhibits a minimum attenuation of 60 dB.

T-only filters are the choice when both the input and output impedances are low.