Discover our high-performance power film capacitors

Are you looking for power film capacitors ? Among its impressive lineup, the FP 20-400-SP film capacitor deserves special attention for its exceptional power-handling capabilities.

Unraveling the FP 20-400-SP

The FP 20-400-SP is a film capacitor that is designed to excel in high-power applications. Here's what sets this capacitor apart:

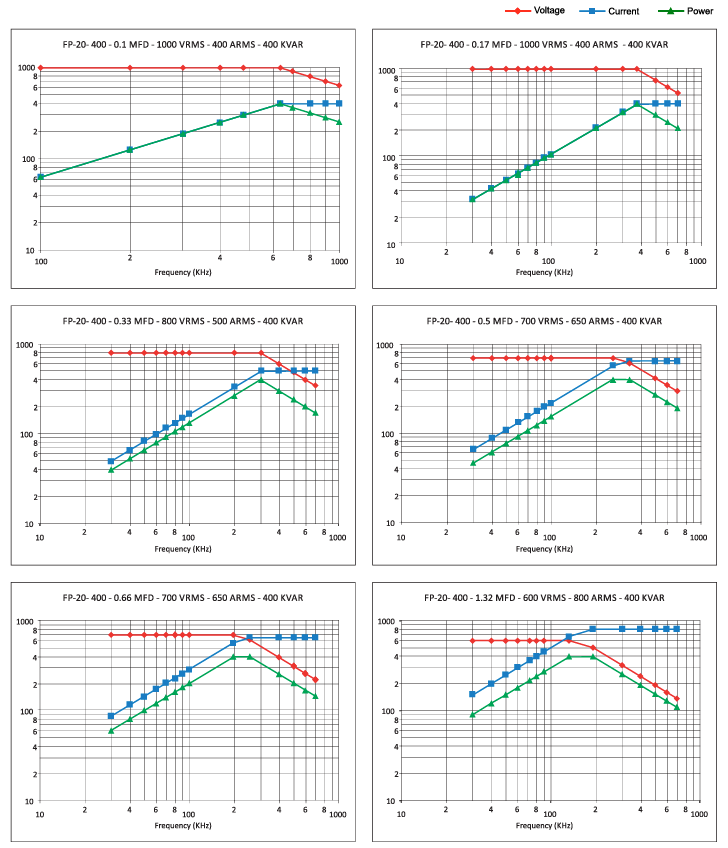

1. High Power Density: The FP 20-400-SP boasts an extraordinary power density, making it an ideal choice for applications where power is of the essence. Its ability to handle high levels of power without compromising on performance is a testament to Exxelia's commitment to excellence.

1. High Power Density: The FP 20-400-SP boasts an extraordinary power density, making it an ideal choice for applications where power is of the essence. Its ability to handle high levels of power without compromising on performance is a testament to Exxelia's commitment to excellence.

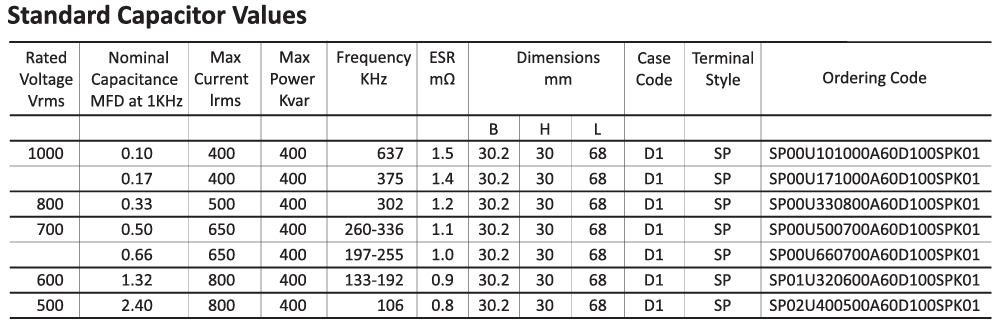

- Very high current (up to 800A)

- Operating frequency up to 1000 KHz

- Capacitance : 0.10 µF - 2.5 µF

- Voltage : 500 VRMS - 1 000 VRMS

- Frequency : 106 kHz - 637 kHz

- Max Power : 400 KVAR

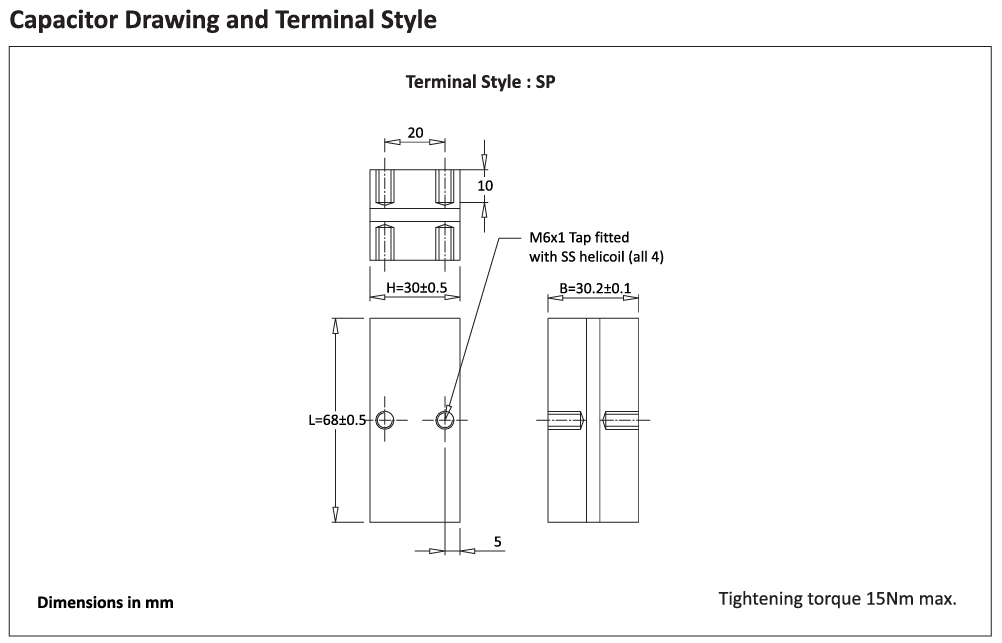

2. Robust Construction: Exxelia's engineering prowess is evident in the robust construction of the FP 20-400-SP. It is built to withstand the rigors of demanding environments, ensuring reliability in critical applications.

3. Wide Temperature Range: this film capacitor operates flawlessly across a broad temperature range (Up to 85 °C with a copper casing to improve temperature management), making it suitable for various industries, including aerospace, defense and renewable energy, where extreme conditions are the norm.

Thanks to an innovative process, we're able to keep the capacitor very dense while maintaining very good electrical characteristics (such as current), and this without impairing the heating of the part.

Applications : In demanding power electronic circuits, this capacitor is a trusted component for smooth operation in Induction heating, electric Cars, medical Imaging, EV Wireless Chargers, resonant Circuits and industrial induction welding.

For more information about this remarkable power film capacitor, visit Exxelia's FP 20-400-SP product page, and also all the Power Film capacitors Exxelia Alcon family.