Exxelia at IMS

Exxelia is pleased to exhibit at IMS in Philadelphia, USA. From June 11 to 15 at booth# 2050, the company will be previewing several high-reliability microwave and RF components dedicated to a variety of industries including medical, transportation and defense.

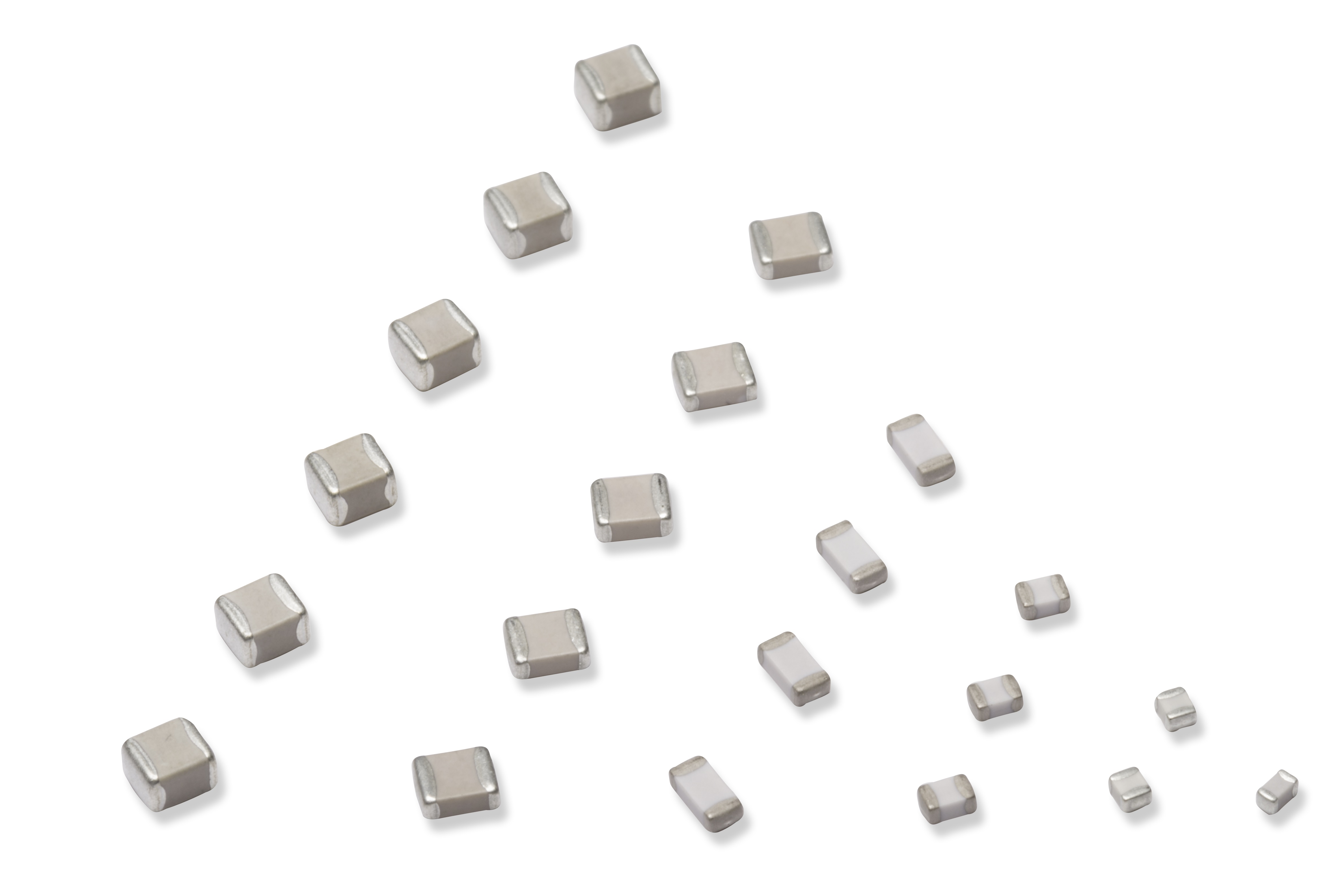

Ultra low ESR, high RF power and high self-resonant frequency

The NHB series is a complete range of MLCC based on NPO dielectric material providing a very high Self Resonant Frequency and limiting the parasite Parallel Resonant Frequencies. The series is available in 1111 size with capacitance ranging from 0. 3pF to 100pF. NHB series offers excellent performance for RF power applications at high temperature up to 175°C and at 500 VDC. The lowest ESR is obtained by combining highly conductive metal electrodes and proprietary of new NPO low loss rugged dielectrics. NHB series particularly fits for high power and high frequency applications such as: cellular base station equipment, broadband wireless service, point to point / multipoint radios and broadcasting equipment. Typical circuit applications: impedance matching, bypass, feedback, tuning, coupling and DC blocking.

The NHB series is a complete range of MLCC based on NPO dielectric material providing a very high Self Resonant Frequency and limiting the parasite Parallel Resonant Frequencies. The series is available in 1111 size with capacitance ranging from 0. 3pF to 100pF. NHB series offers excellent performance for RF power applications at high temperature up to 175°C and at 500 VDC. The lowest ESR is obtained by combining highly conductive metal electrodes and proprietary of new NPO low loss rugged dielectrics. NHB series particularly fits for high power and high frequency applications such as: cellular base station equipment, broadband wireless service, point to point / multipoint radios and broadcasting equipment. Typical circuit applications: impedance matching, bypass, feedback, tuning, coupling and DC blocking.

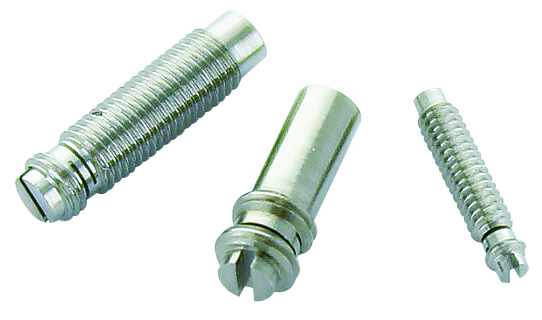

100% invar tuning screws with self-locking system

Invar-36 is a unique Iron-Nickel alloy (64 % Fe / 36 % Ni) sought-after for its very low coefficient of thermal expansion. With 1.1 ppm. K–1 between 0°C and 100°C, Invar-36 is about 17 times more stable than Brass which is the most traditional and common alloy Tuning Elements are made of. The working temperature range in Space is so wide that this property becomes essential for a reliable and stable cavity filter tuning. Self-locking system is a technology commonly used on Tuning Element made of Brass or other soft “easy-to-machine” alloys but is innovative and pretty advanced when applied to hard and tough Invar 36. The design consists of two threaded segments separated by two parallel slots. After cutting both parallel slots, the rotor is compressed in its length in order to create a plastic deformation. Thus, an offset is induced between the two threaded segments which generates a constant tensile stress in the rotor from the moment threaded segments are screwed.

Invar-36 is a unique Iron-Nickel alloy (64 % Fe / 36 % Ni) sought-after for its very low coefficient of thermal expansion. With 1.1 ppm. K–1 between 0°C and 100°C, Invar-36 is about 17 times more stable than Brass which is the most traditional and common alloy Tuning Elements are made of. The working temperature range in Space is so wide that this property becomes essential for a reliable and stable cavity filter tuning. Self-locking system is a technology commonly used on Tuning Element made of Brass or other soft “easy-to-machine” alloys but is innovative and pretty advanced when applied to hard and tough Invar 36. The design consists of two threaded segments separated by two parallel slots. After cutting both parallel slots, the rotor is compressed in its length in order to create a plastic deformation. Thus, an offset is induced between the two threaded segments which generates a constant tensile stress in the rotor from the moment threaded segments are screwed.

High Q Factor Dielectric Resonators in large batches

Dielectric resonators are designed to replace resonant cavities in microwave functions such as filters and oscillators. Exxelia with the support of ESA and CNES developed the E7000 series that provides a narrow bandwidth with smaller size. E7000 is Ba-Mg-Ta materials based that combines an ultra-high Q-factor and the possibility to get all the temperature coefficients upon request. E7000 features the high-performance requested for space use in the frequency range from 5 to 32 GHz, and guarantees up to Qxf > 250 000 at 10GHZ. Being one of the few manufacturers producing its own raw materials, Exxelia perfectly masters the production of dielectric resonators. Induced by the success of this new range, the company is now able to provide larger batches (up to 20kg of powder) of its E7000 series while keeping the exact same product properties, resulting in opportunities for cost-effective volume fabrication.

Dielectric resonators are designed to replace resonant cavities in microwave functions such as filters and oscillators. Exxelia with the support of ESA and CNES developed the E7000 series that provides a narrow bandwidth with smaller size. E7000 is Ba-Mg-Ta materials based that combines an ultra-high Q-factor and the possibility to get all the temperature coefficients upon request. E7000 features the high-performance requested for space use in the frequency range from 5 to 32 GHz, and guarantees up to Qxf > 250 000 at 10GHZ. Being one of the few manufacturers producing its own raw materials, Exxelia perfectly masters the production of dielectric resonators. Induced by the success of this new range, the company is now able to provide larger batches (up to 20kg of powder) of its E7000 series while keeping the exact same product properties, resulting in opportunities for cost-effective volume fabrication.