Transformers

|

Name

|

Download

|

Power

|

Frequency

|

Current

|

Operating Temp

|

Height

|

Mounting

|

Ratio

|

Accuracy

|

|---|---|---|---|---|---|---|---|---|---|

| 3-ph Transformer 150kVA | - |

150kW | 50Hz | - | - | - | Free (In-Line) | - | - |

| 3-ph Transformer 90kVA | - |

90kW | 50Hz ~ 5kHz | - | 200°C | - | Free (In-Line) | - | - |

| Single phase Transformer | - |

125kW | 4000Hz | - | - | - | Free (In-Line) | - | - |

| Integrated sub assemblies | 7kW ~ 2kW | 50Hz ~ 4000Hz | - | - | - | - | - | - | |

| Transformer 40KVA - Lamination assemblies | - |

40 | 60Hz | - | - | - | - | - | - |

| Transformer 60 kVA | - |

60kW | 50Hz | - | -40°C ~ 70°C | - | - | - | - |

| Full Bridge 45kVA-10kHz | - |

45kW | 10kHz | - | 155°C | - | - | - | - |

| Full Bridge 20kVA-100kHz | - |

20kW | 100kHz | - | 155°C | - | - | - | - |

| Push Pull 440W-25 kHz | - |

440W | 25kHz | - | -40°C ~ 130°C | - | - | - | - |

| Forward 35W-180kHz | - |

35W | 180kHz | - | -40°C ~ 85°C | - | Through-hole | - | - |

| Forward 125W-300 kHz | - |

125W | 300kHz | - | -40°C ~ 90°C | - | SMD | - | - |

| Forward 60W-300 kHz | - |

60W | 300kHz | - | -45°C ~ 100°C | 17mm | SMD | - | - |

| Flyback 15W-240 kHz | - |

15W | 240kHz | - | -55°C ~ 125°C | 11mm | SMD | - | - |

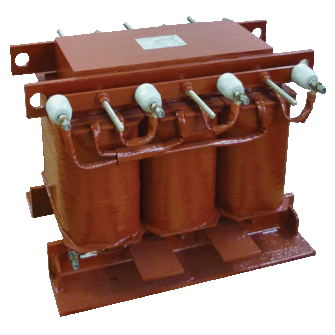

Transformers

Exxelia excels in designing and manufacturing transformers tailored for DC/DC converters, Standard network frequency 50/60Hz, switch mode power supplies (SMPS), and 400Hz power supplies integral to aircraft electrical systems, as well as for inverters and chargers. Our expertise allows for the creation of products that minimize weight, footprint, and losses, optimizing performance across applications.

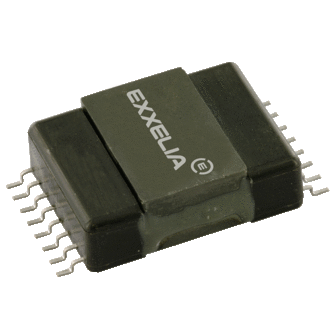

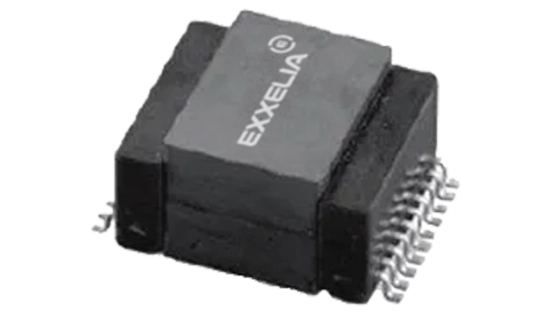

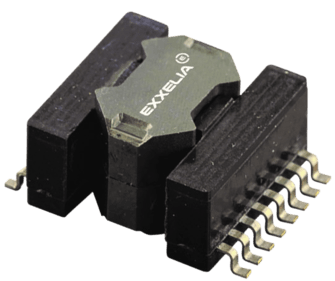

Our power transformers for SMPS utilize advanced technology packages, including Exxelia technology platforms SESI, CCM25, standard and specific package using (ferrite, nanocrystalline, cores, available in both through-hole, surface-mount and device (SMD) configurations. These transformers are engineered to meet the rigorous demands of aerospace, railways, defense, medical and energy sectors, ensuring reliability and efficiency in critical applications. Specialized designs include SMPS Transformers: Flyback, Forward, Push Pull, Half Bridge, Full Bridge, Dual Active Bridge, DAB, LLC transformers, resonant, and Pulse Transformers: Gate Drive Transformers, Data Bus 1553.

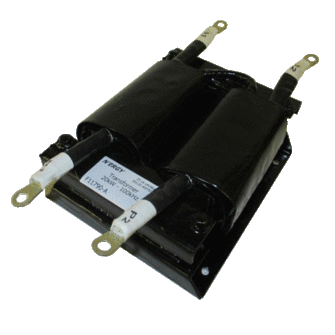

Exxelia also specializes in high-power and high-voltage magnetics designed for demanding environments in mass-transit, railway, and premium industrial applications. These magnetics are crafted to offer superior performance under the most challenging conditions. Current Transformers High Accuracy are a key offering.

Furthermore, Exxelia produces a range of data transformers for communication buses and data transmission networks, crafted to endure harsh conditions while complying with the MIL-STD 1533 standard. Available in both SMD and through-hole packages, these transformers meet stringent military specifications.

In addition to our extensive transformer and inductor offerings, Exxelia provides solutions that emphasize volume and weight reduction, alongside enhanced heat dissipation. Our innovative cooling techniques, including direct and indirect fluid cooling or cold plate systems, ensure that our products deliver superior performance while maintaining operational efficiency and reliability in demanding applications. Multi Pulse Transformer for “400Hz” & Power Supply and 50/60 Hz Transformer for Niche Markets are examples of our specialized solutions.